What are gate valves

Gate valves are valves that have much popularity when it comes to all types of applications and attachments and is therefore suitable for both above-ground and underground installation. When installing gate valves underground, it is vital to pick the appropriate type of valve to avoid high replacement costs.

Gate valves are made for either fully open or fully closed services. They are installed in pipelines, similar check valves, as isolation valves and definitely should not be utilized as regulation or moderation valves. Operation on a gate valve usually occurs doing either clockwise to close or clockwise to open rotating motion of the steam. When operating the valve, the gate moves either up or downwards; not sideways.

Where are gate valves used?

Gate valves are usually used when free bore and minimum pressure loss are the requirements. When the pipeline is fully open, a typical gate valve has no obstruction in the flow path, which results in an extremely low-pressure loss. This design makes it possible to use a pipe-cleaning pig.

A gate valve is a multi-turn valve, meaning that the operation of the valve is finalized by means of a threaded stem. As the valve has to turn many times to go from an open to a closed position, the operation also stops the effects of the water hammer.

Gate valves can be used for a plethora of different fluids. The products from China Gate Valve Manufacturer are commonly suitable for under the following working conditions:

- Neutral, wastewater and potable water: temperatures somewhere between -20 and 70+ degrees Celsius, maximum 5 m/s flowing speed, and limited up to 16 bar differential pressure.

- Any gases: temperatures between -20 and +60 degrees Celsius, maximum flowing speed: 20 m/s flow velocity, and reaching up to 16 differential pressure.

Gate valves with bypass

Bypass gate valves are primarily used for three simple reasons:

- Delayed filling of pipelines

- With the main valve closed, and the bypass valve opens, a consistent flow is allowed, preventing possible stagnation

- To balance the pipeline’s differential pressure, lowering the torque requirement of the valve and allow one-man operations

Parallel vs Wedge-Shaped Gate valves

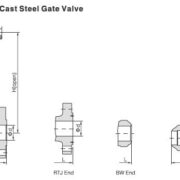

Gate valves can be divided into two alpha types: Parallel and wedge-shaped. The difference is that parallel gate valves use a flat gate between two parallel (thus where their name originates) seats, and a popular variant is the knife gate valve designed with sharp edges on the bottom of the gate. The wedge-shaped gate valves used two inclined seats and a mismatched inclined gate.

Metal seated vs resilient seated gate valves

Before the resilient seat gate valve was mass-manufactured, gate valves including a metal seated wedge were widely used. The pointed wedge structure and angular sealing devices of a metal seated wedge need a bore of the valve’s bottom to confirm a tight closure. Therefore, sand and pebbles are embedded in the depression. The pipe network will never be fully free from impurities. Regardless of how well the pipe is flushed during installation or repair.