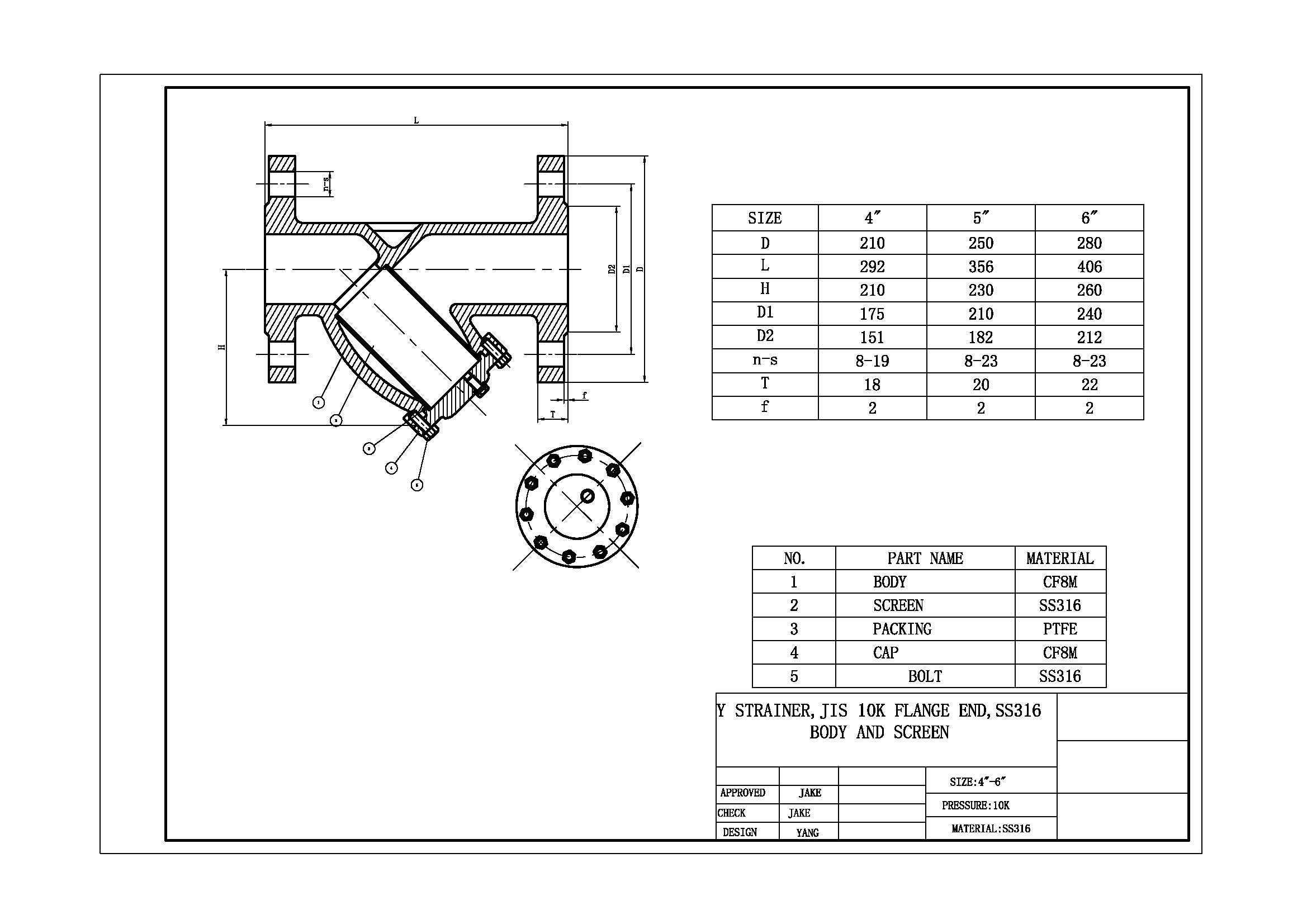

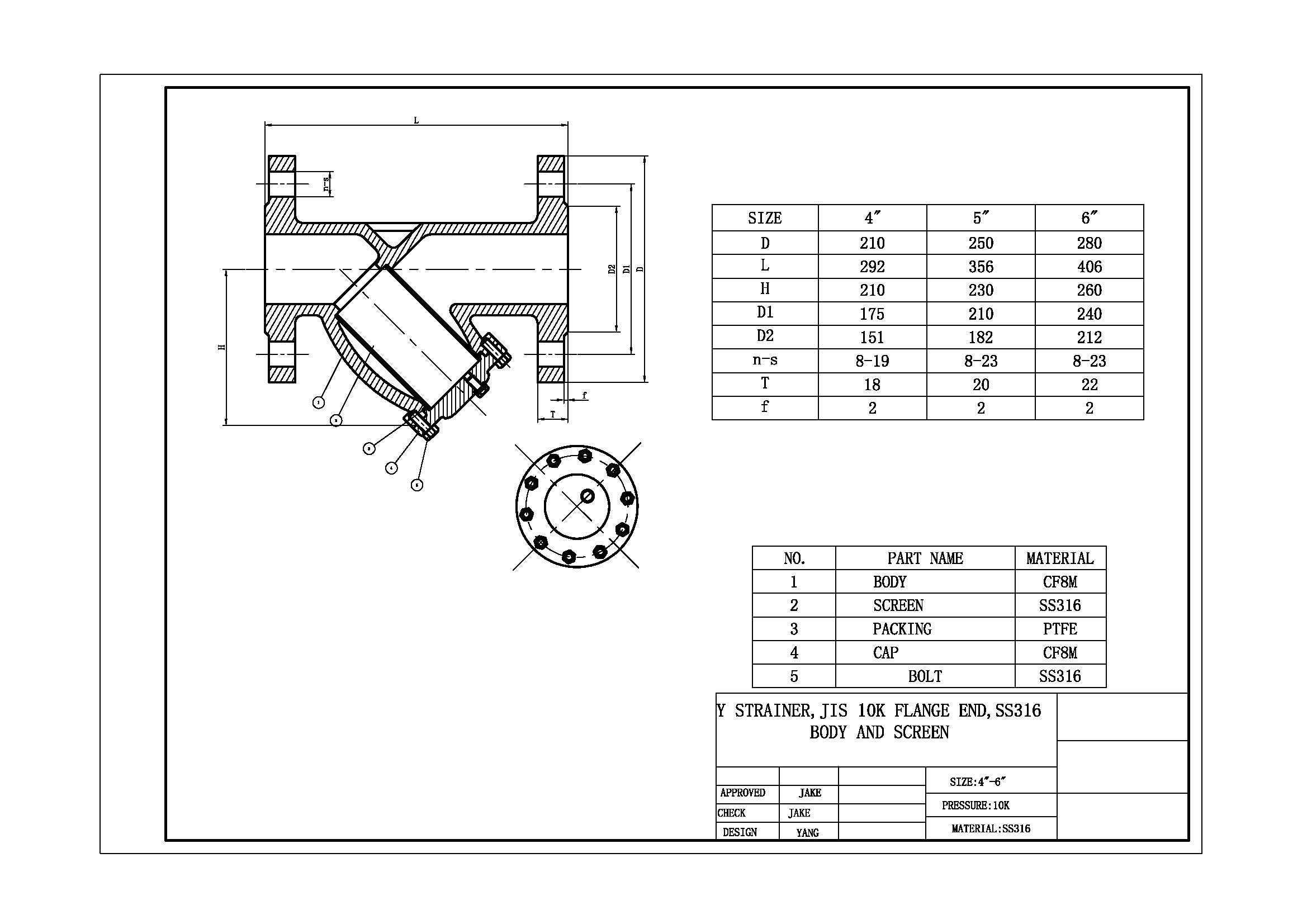

Y-type Strainer is mainly composed of nozzle, main pipe, filter, flange, flange cover and fasteners. When the liquid enters the basket through the main tube, the solid foreign particles are blocked in the filter blue, and the clean fluid passes through the filter basket and is discharged from the filter outlet.

The Y-type Strainer is an indispensable filter device in the piping system for conveying fluid medium.

Y-type Strainer are usually installed in the pressure reducing valve, pressure relief valve, shut-off valve (such as the inlet end of the indoor heating pipe) or the inlet end of other equipment to remove impurities in the medium to protect the normal operation of the valve and equipment. use. The Y-type Strainer has advanced structure, low resistance and convenient sewage discharge.

The reason why the filter is made into a cylindrical filter basket shape is to increase its strength and is stronger than a single-layer net. The flange cover at the lower end of the y-shaped interface can be unscrewed, and the particulate impurities deposited in the filter basket are periodically removed. .

Second, the installation method

The Y-type Strainer works by installing it at the inlet end of the device to remove impurities from the media to protect the valve. The correct installation method is horizontal installation or vertical downward installation. I. Working principle

Carefully clean the threaded joint surfaces of all pipes before installing the filter. Use pipe sealant or Teflon tape (polytetrafluoroethylene) for proper amount.

The end threads are not treated to avoid entering the sealant or Teflon tape into the piping system. The filter can be installed horizontally or vertically downwards.