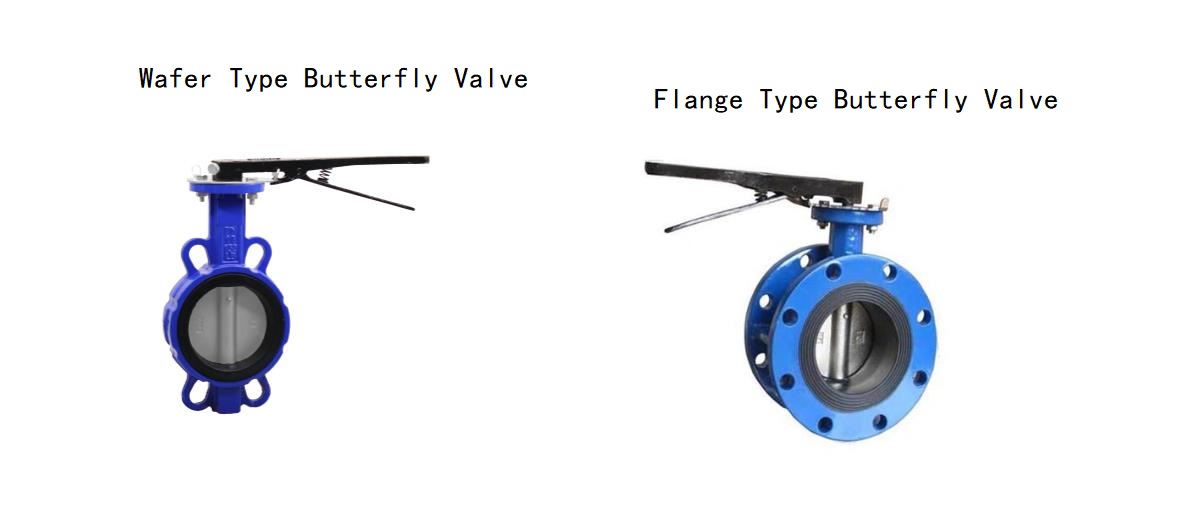

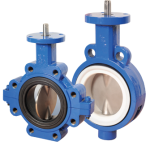

The difference between flanged butterfly valve and wafer butterfly valve

Butterfly valves are not only widely used in general industries such as petroleum, gas, chemical, water treatment, but also in the cooling water system of thermal power plants. Wafer and flange are two connection methods. Flanged butterfly valve has flanges at both ends of the valve body, which are connected with pipe flanges. The wafer type butterfly valve body has no flanges at both ends, only a few pilot bolt holes, and the valve is connected with the flanges at the ends with a set of bolts/nuts. The clip-on is cheap and lightweight. When choosing imported valves, use the wafer type as much as possible, which is cheap.

Wafer-type valve bolts are long in length and require higher construction accuracy. If the flanges on both sides are misaligned, the bolts will be subject to greater shearing force and the valve will easily leak.

In contrast, the wafer butterfly valve is easier to disassemble, and the cost of the valve is lower, but the disadvantage is that there is a problem with one sealing surface, and both sealing surfaces have to be disassembled.

Flanged butterfly valve seals are relatively more reliable, but the cost of the valve is relatively high.

Moreover, the wafer type butterfly valve generally cannot be used at the end of the pipeline and where the downstream needs to be disassembled, because when the downstream flange is disassembled, the wafer type valve will fall off. In this case, another short joint must be made. It is easy to disassemble, and the flanged butterfly valve does not have the above problems, but the cost will be relatively high.

Wafer-type valve bolts are generally relatively long. Under high temperature conditions, the expansion of the bolts may cause leakage, so it is not suitable for large pipe diameters under high temperature conditions.

The Wafer type Butterfly Valve is placed between pipe flanges, and the flange bolts surround the valve body. The Wafer Type Butterfly Valve is suitable for most flanges (including Table E, PN16 and Ansi150). If either side of the valve needs maintenance, then the entire line must be shut down.

CHINA BUTTERFLY VALVE MANUFACTURER

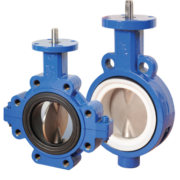

STV produces and offer electric butterfly valve, pneumatic butterfly valve, manual butterfly valve, wafer butterfly valve, flange butterfly valve, stainless steel butterfly valve and other manufacturers, designing national standard butterfly valve, chemical department butterfly valve, mechanical butterfly valve and export type ANSI standard butterfly valve, DIN standard butterfly valve, JIS Butterfly valve.

Both lug and wafer butterfly valves are used in a number of applications for industrial sectors that include food processing, pharmaceutical, chemical, oil, water as well as waste water management. The valves utilized in these industries are generally manufactured in compliance with the “Pharmaceutical Quality/Manufacturing Standard”, cGMP (current good manufacturing practice) guidelines. Butterfly valves for the most part have replaced ball valves in a lot of industries. This is especially the case for those dealing with petroleum because of they are less expensive and easy to install. It’s important to note that pipelines that contain butterfly valves can’t be ‘pigged’ for cleaning. “Pigging” is the process of making use of devices referred to as “pigs” to carry out a variety of maintenance operations.

Both lug and wafer butterfly valves are used in a number of applications for industrial sectors that include food processing, pharmaceutical, chemical, oil, water as well as waste water management. The valves utilized in these industries are generally manufactured in compliance with the “Pharmaceutical Quality/Manufacturing Standard”, cGMP (current good manufacturing practice) guidelines. Butterfly valves for the most part have replaced ball valves in a lot of industries. This is especially the case for those dealing with petroleum because of they are less expensive and easy to install. It’s important to note that pipelines that contain butterfly valves can’t be ‘pigged’ for cleaning. “Pigging” is the process of making use of devices referred to as “pigs” to carry out a variety of maintenance operations.