what is the different Difference between ball valve and globe valve

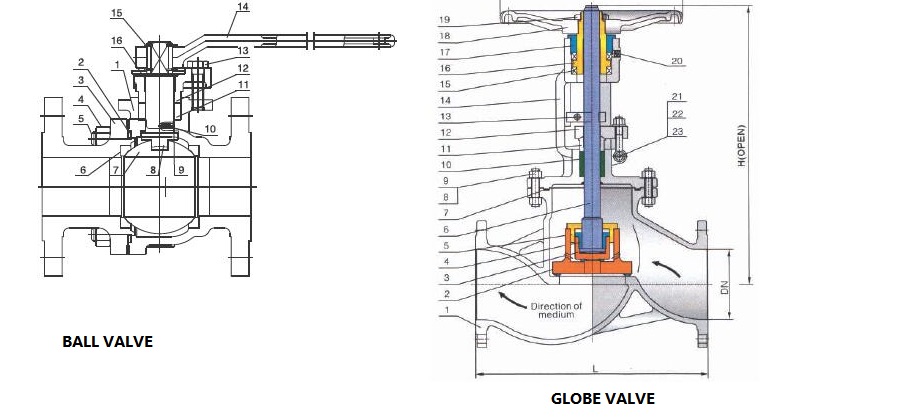

There are many different types of valves for different applications, so how do you know which is the best to use for your application? Let’s look at globe valves and ball valves. The main difference between these two types is the way they close. A globe valve uses a plug (stem) that closes against the flow, and a ball valve has a gate (ball) that closes across the flow. Globe valves are good for regulating flow, whereas ball valves are better for on/off control without pressure drop.

For decades globe valves were considered the industry standard in control valves. They are designed with a stem that moves up and down inside the valve to control flow. They are commonly used on hot and chill water coils, and larger models are often used to control flow to chillers. One of the main limitations of globe valves is that their close-off rating can be lower than other valves, especially in the larger sizes.

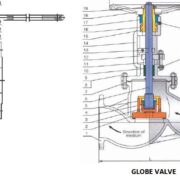

Ball valves are designed with a ball inside the valve. The ball has a hole through the middle so that when the hole is in line with both ends of the valve, flow will occur. When the valve is closed by turning the ball 90 degrees, the hole is perpendicular to the ends of the valve, and therefore flow is blocked. Ball valves are very durable and usually have excellent shutoff even after years of use. They are generally preferred over globe valves in shutoff applications. The main limitation for ball valves is proportional control because of the large amount of flow that the ball allows.

The key difference between a globe and a ball valve is that a ball valve is designed, mainly, for shut-off operations, whereas a globe valve is designed, mainly, to throttle fluids. These two valves are industry-standards respectively for shut-off (ball valve) and for regulation (globe valve) applications.

A globe valve does not fit shut-off operations, due to the pressure drop it creates in the piping system (a problem that does not exist for full bore ball valves).

Ball valves have a long service life even in case of continuous on-off operations; globe valves would deteriorate easily under this type of service.