Stainless steel pneumatic ball valve manufacturers introduce the main features of the ball valve

Stainless steel pneumatic ball valve main features

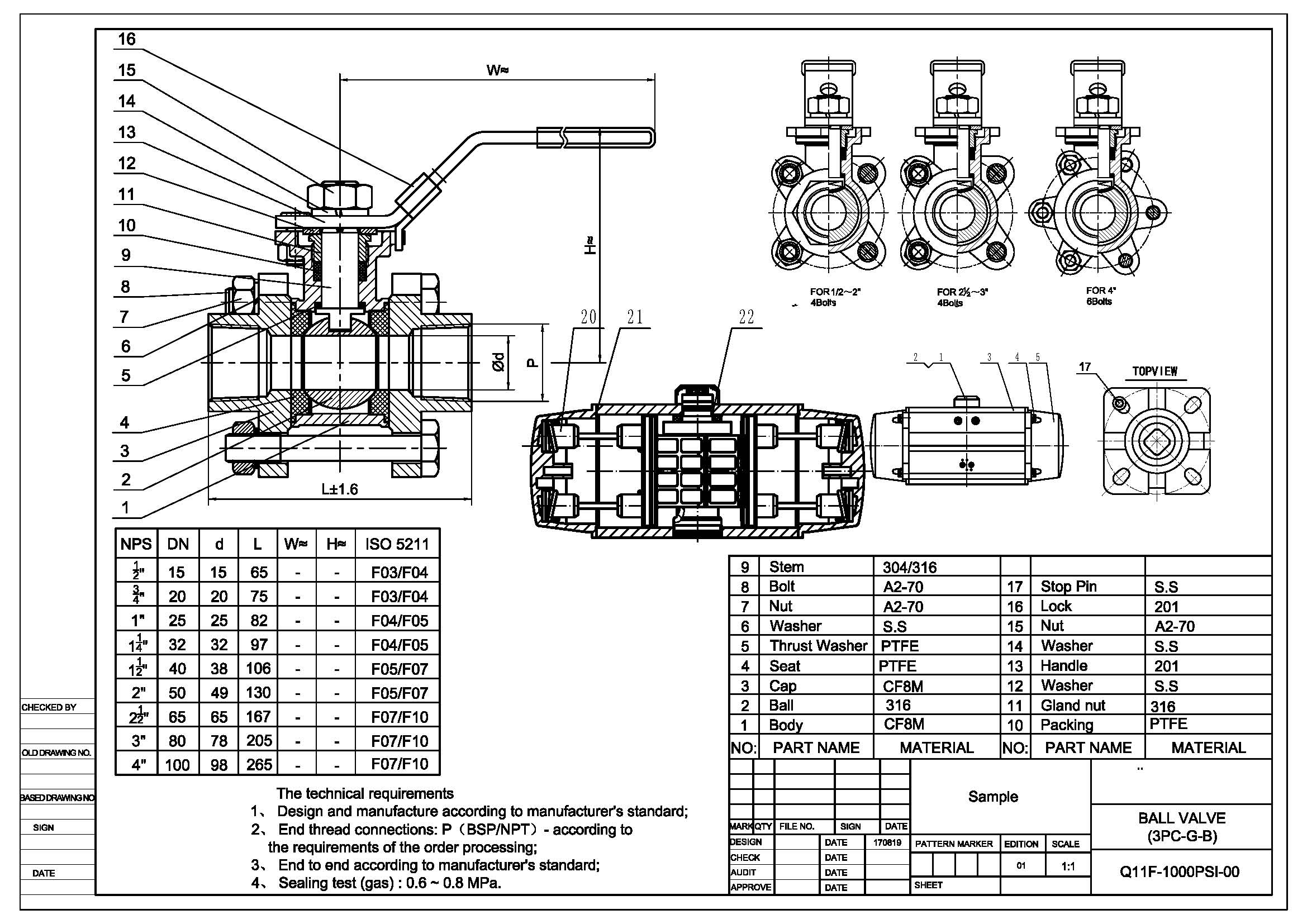

1. The manual part can be made of steel plate pressed handle or stainless steel cast handle. The handle has a limit structure, and the limit is set at the position where the valve is opened and closed. When the valve is used on the key device, the lock block is provided with a lock hole to lock the switch position to avoid misoperation. There are obvious opening and closing signs on the handle.

2. The valve stem is integrally forged and conditioned by Q641F stainless steel pneumatic ball valve manufacturer 182f (1cr13), and the hardness reaches hb220~250. The valve stem is connected to the handle through a flat key or a spline or a deed, which is versatile and easy to assemble and disassemble. The valve stem is provided with an anti-blowing structure.

3. The valve packing is made of braided, flexible graphite sealing ring or tetrafluoroolefin sealing ring, which makes the valve stem achieve reliable sealing under certain lubrication conditions.

4. According to the needs, the ball valve can be designed as an anti-static structure. A conductive spring is arranged between the ball and the valve stem, the valve stem and the valve body to avoid electrostatic ignition and ignite flammable substances to ensure system safety.

5. The sealing pair has various forms. According to different working conditions, soft seal, hard seal, fireproof seat and other structures can be selected; below dn150 is the form of float ball, and below dn200 is fixed ball form.

6. The auxiliary valve sealing structure can be set at the valve seat of the ball valve. The grease filling valve can be installed at the valve seat and the valve stem. It can be temporarily sealed in case of emergency, and the valve stem can be lengthened as needed to be buried.