Installation and removal of pneumatic angle seat valve

Function of pneumatic angle seat valve:

The pneumatic angle seat valve can save space by keeping the flow rate. It uses a single acting pneumatic actuator with spring safety protection to operate the guide angle seat valve. When using, it should choose normally open or normally closed.

The pneumatic angle seat valve is widely used for frequent starting in a short time. It has the characteristics of sensitive response and accurate action. With the use of the solenoid valve, the pneumatic control can accurately control the flow of gas and liquid. It can realize the requirements of accurate temperature control and liquid dropping. The angle seat valve shall be used to control the steam volume and accurately control the temperature in the damp heat sterilization cabinet.

Brief description of pneumatic angle seat valve:

*Large flow, small flow resistance, no water hammer;

*Ultra long service life;

*Modular universal accessories can be installed on the normally open or normally closed universal cylinder actuating head;

*The standard supply includes the flow direction under the valve seat or up the valve seat;

*Circuit functions can be easily changed.

Installation and removal of pneumatic angle seat valve:

1. Connect the valve to the pipeline, and ensure that the arrow attached to the valve body is consistent with the fluid direction (the arrow outside the valve body represents the fluid flow direction, please follow the installation);

2. Welding installation: please remove the actuator during welding;

3. Thread, flange and quick installation: can be installed normally;

4. Disassembly: ensure that the air pressure to the valve has been relieved before disassembly; Light unloading; Protect the threads and sealing materials after disassembly;

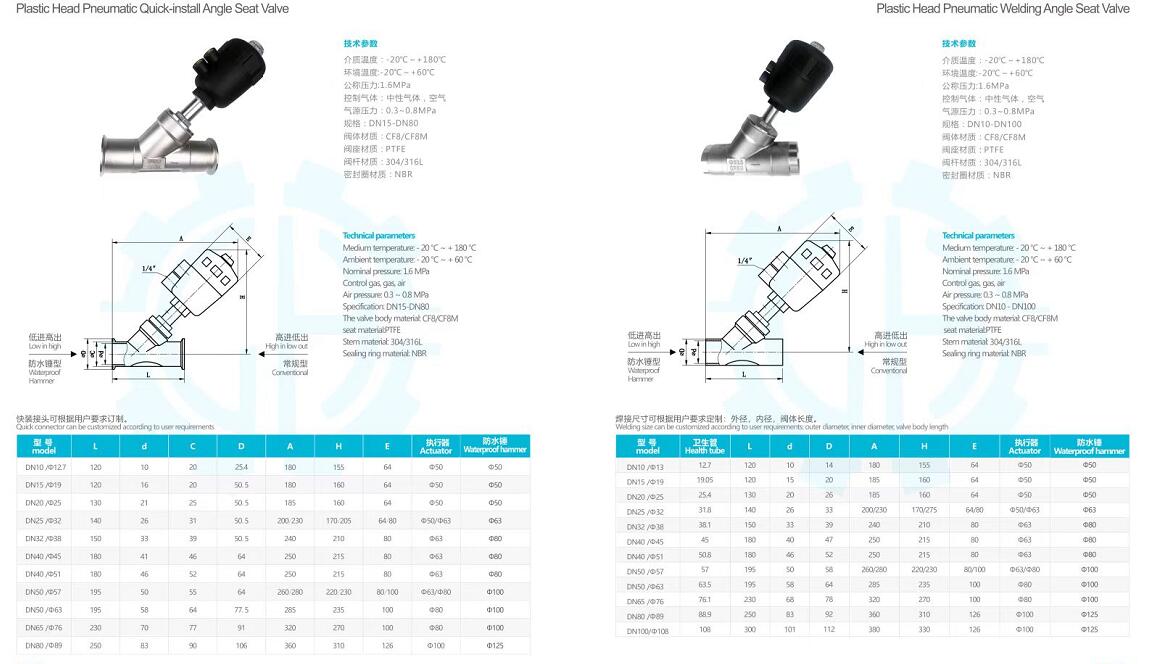

5. Sufficient torque is required for the connection and fastening of valve body and pipeline. The torque values of each dimension are as follows: DN15 is 40Nm, DN20 is 50Nm, DN25 is 70Nm, DN32 is 150Nm, DN40 is 150Nm, DN50 is 170Nm, DN80 is 240Nm, and DN100 is 300Nm.

6. During installation, please ensure that there is no residue in the pipe and at the interface.

7. After installation, the inspection and connection parts shall be sealed well without leakage before use.

Pneumatic angle seat valve is widely used in the fields of canning, bottle system, beer brewing and beverage technology, chemical industry, rubber machinery, food industry, textile dyeing and bleaching, vacuum technology, water treatment device, cleaning, disinfection, high-temperature sterilization, washing machinery, etc

China pneumatic angle seat valve Manufacture,pneumatic angle seat valve Supplier