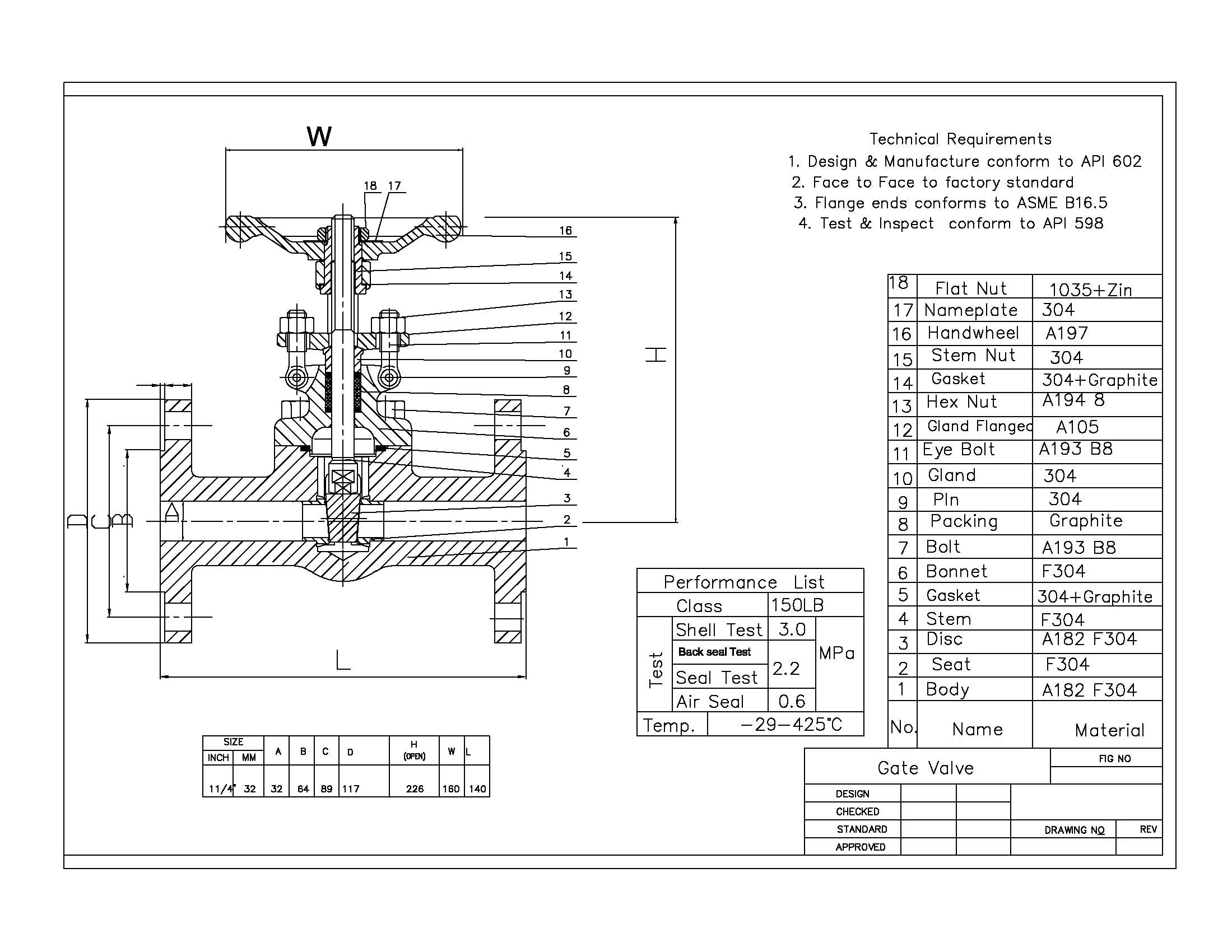

What Is The Particularity and production of integral flange forged steel valves

The speciality and production of the integral flange forged steel valve, the integral flange forged steel valve is mainly applicable to the pipelines of various systems of the thermal power station, cutting or connecting the pipeline medium. Applicable medium: non-corrosive medium such as water and steam. Compared with other valve products, the integral flange forged steel valve is characterized by high temperature and high pressure and unique self-sealing design. The higher the pressure, the more reliable the seal. Due to the special technical characteristics and working conditions, the products also form features that cannot be replaced by other products.

Integral flange forged steel valve

This paper introduces the integral flange forging steel valve body die forging method, which is to take the blanking, pre-forging, final forging and trimming in turn. The characteristics are pre-forged initial blank after blanking, which is to forge the outer diameter of the material to be larger than the valve. The outer diameter of the flange on both sides of the body is flattened, and the thickness of the middle flattened is larger than the outer diameter of the flange in the valve body, and the initial shape blank having a length greater than the length of the flange on both sides of the valve body is formed. For the blanking, the blanks after the blanking are placed in the upper and lower molds for final forging in one-way die forging, and the final forging is performed after trimming. Further, for the small-diameter flange valve, since the flanges on both sides are close to the middle flange, in order to ensure the unidirectional die forging process, the residual amount is sufficient to simultaneously discharge the waste to the two adjacent flange positions, at the side flange and There is a gap between the upper and lower mold edges between the middle flanges.