How to Select Gate Valve Materials

The material selection of gate valve mainly depends on the fluid medium and working environment. According to the different medium and environment, the material selection is also different. Generally speaking, the material selection of valve is divided into three aspects; the sealing surface of valve disc, in which the valve body is generally made of carbon steel cast iron (gray cast iron ductile iron) stainless steel (304 316) and the valve plate is made of carbon steel stainless steel (304 316) dual phase steel (2507 316) Generally, the sealing surface of nylon coating lining fluorine has: NBR EPDM PDEF ppl. Customers can choose the corresponding material according to their actual needs. Please contact our sales staff and look forward to cooperating with you.

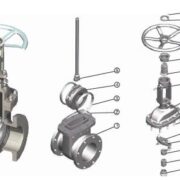

BODY

TRIM

The removable and replaceable parts of the valve are collectively defined as “trim” (for a gate valve: seat, disc, backseat and, stem).

The API 600 specification foresees a number of standard trim combinations, as illustrated below

| API TRIM # | BASE MATERIAL | MATERIAL FOR SEAT | MATERIAL FOR DISC | BACKSEAT MATERIAL |

MATERIAL FOR STEM |

|---|---|---|---|---|---|

| 1 | 410 | 410 | 410 | 410 | 410 |

| 2 | 304 | 304 | 304 | 304 | 304 |

| 3 | F310 | 310 | 310 | 310 | 310 |

| 4 | Hard 410 | Hard 410 | 410 | 410 | 410 |

| 5 | Hardfaced | Stellite | Stellite | 410 | 410 |

| 5A | Hardfaced | Ni-Cr | Ni-Cr | 410 | 410 |

| 6 | 410 and Cu-Ni | Cu-Ni | Cu-Ni | 410 | 410 |

| 7 | 410 and Hard 410 | Hard 410 | Hard 410 | 410 | 410 |

| 8 | 410 and Hardfaced | Stellite | 410 | 410 | 410 |

| 8A | 410 and Hardfaced | Ni-Cr | 410 | 410 | 410 |

| 9 | Monel | Monel | Monel | Monel | Monel |

| 10 | 316 | 316 | 316 | 316 | 316 |

| 11 | Monel | Stellite | Monel | Monel | Monel |

| 12 | 316 and Hardfaced | Stellite | 316 | 316 | 316 |

| 13 | Alloy 20 | Alloy 20 | Alloy 20 | Alloy 20 | Alloy 20 |

| 14 | Alloy 20 and Hardfaced | Stellite | Alloy 20 | Alloy 20 | Alloy 20 |

| 15 | 304 and Hardfaced | Stellite | Stellite | 304 | 304 |

| 16 | 316 and Hardfaced | Stellite | Stellite | 316 | 316 |

| 17 | 347 and Hardfaced | Stellite | Stellite | 347 | 347 |

| 18 | Alloy 20 and Hardfaced | Stellite | Stellite | Alloy 20 | Alloy 20 |

MATERIAL SELECTION

| TRIM | RECOMMENDED SERVICE |

|---|---|

| 13% Cr, Type 410 Stainless Steel | For oil and oil vapors and general services with heat treated seats and wedges. |

| 13% Cr, Type 410 plus Hardfacing | Universal trim for general service requiring long service life up to 1100°F (593°C).* |

| Type 316 Stainless | For liquids and gases which are corrosive to 410 Stainless Steel, up to 1000°F (537°C).* |

| Monel | For corrosive service to 842°F (450°C) such as acids, alkalies, salt solutions, etc. |

| Alloy 20 | For corrosive service such as hot acids -49°F to 608oF (-45°C to 320°C). |

| NACE | Specially treated 316 or 410 trim combined optionally with B7M Bolts and 2HM nuts to meet NACE MR-01-75 requirements. |

| Full Stellite | Full hard faced trim, suitable for abrasive & severe services up to 1200°F (650°C). |