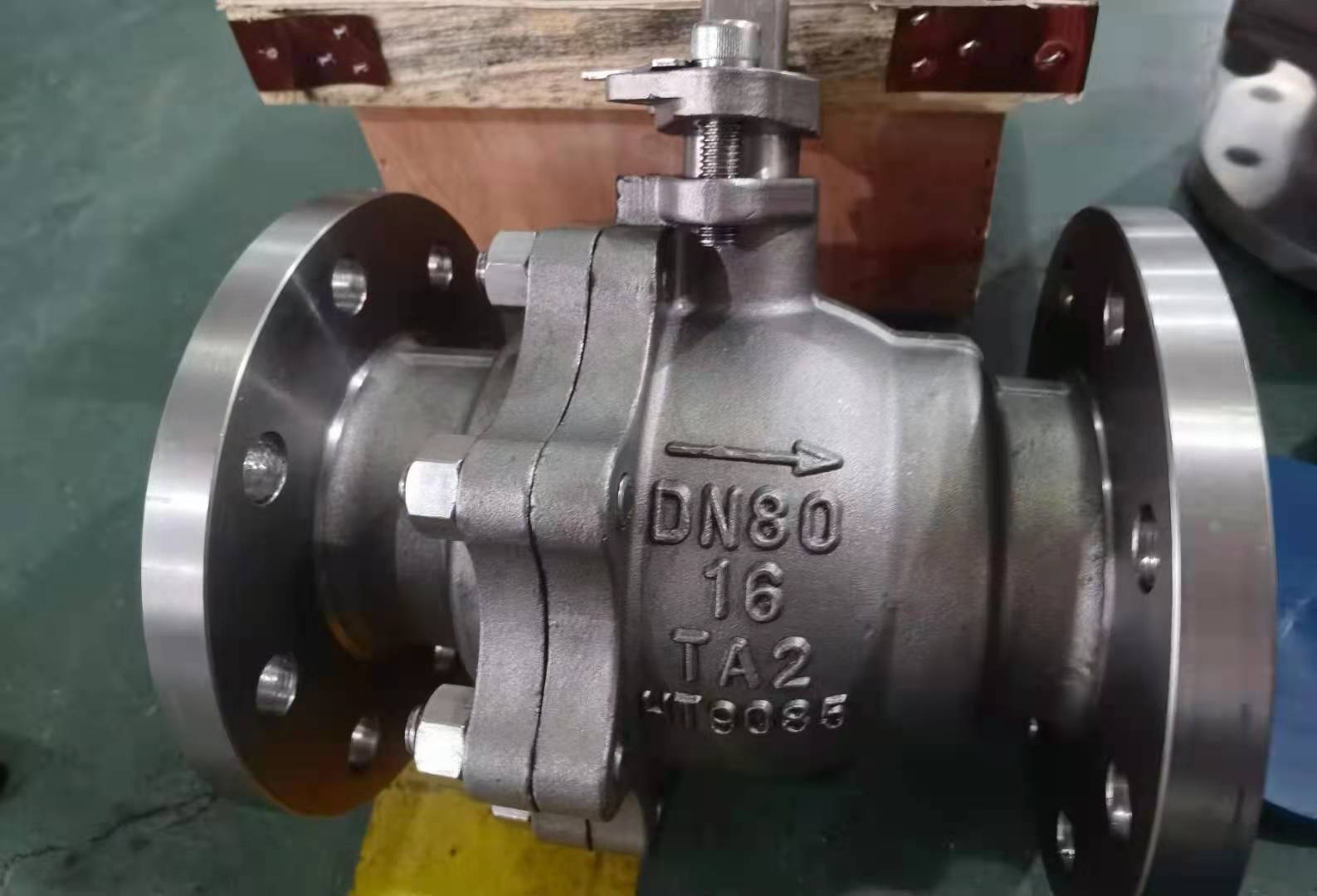

Titanium Ball Valve manufacturer in China

Introduction to titanium ball valve:

Titanium flanged ball valve has reliable sealing, simple structure, sealing surface and spherical surface are often closed, not easy to be eroded by media, and easy to operate and maintain. It is suitable for general working media such as water, solvent, oil, gas, acid and natural gas, and also suitable for media with poor working conditions, such as oxygen, hydrogen peroxide, methane and ethylene. It is widely used in various industries. The valve body can be integral or combined.

Working principle of titanium ball valve:

Titanium flanged ball valve has a 90 degree rotation action. The cock body is a sphere with a circular through hole or channel passing through its axis. It is mainly used to cut off, distribute and change the flow direction of the medium in the pipeline. It can be closed tightly with only 90 degree rotation operation and small rotation torque. It is most suitable for use as a switch and shut-off valve, as well as for throttling and flow control.

Features of titanium products:

1. Locking device: in order to prevent the wrong operation of the valve switch, there are locking holes in the fully open and fully closed positions of the valve to ensure that the valve is in the correct position.

2. Handle with correct switch: Flat head valve rod is used, and the connection with the handle will not be misplaced, so as to ensure the switch state indicated by the handle and the speech of valve I.

3. Valve rod anti flying structure: the valve rod is bottom mounted to prevent it from flying out under pressure. At the same time, it can form metal contact with the valve body after a fire to ensure valve rod sealing.

4. Advanced valve seat: the valve seat is designed based on years of experience in ball valve manufacturing to ensure valve sealing, with low friction coefficient, small operating torque, multiple valve seat materials and wide application range.

STV Valve Technology Group Co., Ltd is a professional leader 2PC DIN Ti Ball Valve ,4 Inch Ti Ball Valve in China,DIN Ti Ball Valve,DN100 Ti Ball Valve,PN16 Ti Ball Valve,Lever Operation Ball Valve Manufacture.

Titanium material characteristics:

TA1, TA2 and TA3 are industrial pure titanium. They can be welded in various forms with good welding performance. The welded joint can reach 90% of the strength of the base metal. It is easy to cut by sawing and grinding wheel, and has good machining performance. Excellent corrosion resistance is used for parts under 350 ℃ with small force and parts stamped into various complex shapes. For example, thermal power plant condenser; Pipeline systems, valves and pumps corroded by marine seawater; Chemical heat exchanger, pump body, distillation tower; Seawater desalination system, platinum plated anode; The frame, skin, engine parts, beam, etc. of the aircraft. Titanium is characterized by low mass (density 4.51g/cm3), high strength, excellent corrosion resistance, and good low-temperature performance. It has excellent corrosion resistance in seawater and most acid, alkali and salt media. In urea production, its corrosion resistance is 10 times higher than that of carbon austenitic stainless steel. For example, in salt production, the preheater made of red copper tube was severely corroded after several months of use and was renewed after 10 months. The chloride ion has no corrosion on the titanium equipment. The salt slurry pipe is corroded after being made of carbon steel for half a month, which is honeycombed. The salt slurry pipe should be replaced 6 times a year; It is made of stainless steel and can be perforated in 4 months. The titanium tube has been used for 4 years, but no corrosion perforation has occurred. The one-time investment of titanium equipment is high, the life cycle cost is relatively low, and the economic benefits are very obvious.

STV Valve Technology Group Co., Ltd is a professional leader 2PC DIN Ti Ball Valve ,4 Inch Ti Ball Valve in China,DIN Ti Ball Valve,DN100 Ti Ball Valve,PN16 Ti Ball Valve,Lever Operation Ball Valve Manufacture.