What is The Different 3 Piece Ball Valve and 2 Piece Ball Valve

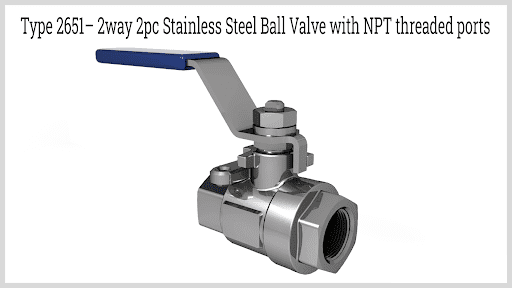

The 2 piece ball valve is called the stainless steel ball valve, which is composed of the left and right valve bodies bolted together. When fixing, the two valve bodies clamp the ball valve, which is relatively difficult to maintain. The key is to see how tight the screw in the middle is, which is directly related to whether the seal is tight. In addition, it is mainly used in atmospheric and high-pressure environments, and non-standard valves with nominal diameters below DN50 also belong to the 2 piece type. A 2 piece ball valve is a commonly used valve that is fixed by clamping the ball with two valve bodies, and maintenance is complex. The tightness of the middle screw is crucial, which determines whether there is air leakage.

The three piece ball valve is similar to the two piece ball valve, but the three piece ball valve can be used in ultra-high pressure environments, and the valve structure design will have a three piece valve body, which is clamped and fixed by the left and right neck flanges. The normal nominal diameter is above DN50. The three piece ball valve is somewhat similar to the two piece ball valve, but there are multiple valve bodies in the middle of the ball, which are clamped by neck flanges on both sides. Commonly used larger and more important valves.

Advantages Of 2 Piece Ball Valves

The best way to understand the differences between a 3 piece vs 2 piece ball valve, is to understand the advantages of both. Listed below are the advantages of 2 piece ball valves.

Easy To Install: 2 piece ball valves are lightweight, small, and have a simple structure. Its small diameter ensures that it is easy to install, and the small actuator size facilitates frictionless movement.

Minimal Fluid Resistance: In this type of ball valve, the resistance coefficient is equal to that of a pipe of the same length, which means that fluids can flow through seamlessly.

Good Sealing Performance: These ball valves close tightly and have a strong seal, which gives them high sealing performance, hence, reducing the possibility of leakage. Materials like metal, EPR, EPDM, and PTFE are used on the sealing surface.

Operational Convenience: 2 piece ball valves can be swiftly opened and closed as desired when rotated to a complete right angle. It can also be remotely operated if required.

Easy Maintenance: The valve structure is simple, which makes it easy to maintain. When it is fully open or closed, the seat sealing surface is isolated from the fluid, which minimizes the risk of erosion of the sealant.

Applications

2 piece ball valves can be used for a variety of applications since their diameter can vary from a few millimetres to a few meters. Its simple structure, high sealing performance, and operational convenience make it ideal to be used under high pressure or vacuum conditions. 2 piece ball valves are typically used in foodservice equipment, automotive fluid filling devices, and liquid filling equipment.

A 3 piece ball valve comprises three pieces, specifically, a pair of connecting ends and the main body. The end cap can be connected to the pipeline via a flanged, welded, clamped, or threaded assembly.

One of the most significant advantages of 3 piece ball valves is that they are easy to disassemble. Its central body can be removed for maintenance and cleaning without disrupting the entire pipeline’s functioning.

Once cleaned and serviced, the central body can be reattached to the end caps without any hassle, hence, reducing maintenance costs. If the price of a 3 piece ball valve vs 2 piece ball valve is compared, the former is more expensive but can be cheaper in the long run since maintenance costs are reduced.

Advantages Of 3 Piece Ball Valves

- Sound design: Since this type of valve has three pieces and it has a simple, lightweight design, it can easily be assembled or installed and disassembled with no hassle.

- Fluid Resistance Is Low: The resistance coefficient is equal to the pipe diameter of the same length for 3 piece ball valves. This ensures that fluids can flow easily, and it reduces the chance of blockages being formed. In addition, most of these valves are full bore designs, which allows more fluids to be transported.

- High Sealing Performance: Changing seals and seats is more cost-effective in this type of ball valve. Since they close tightly when welded, it forms a strong seal that prevents leaks.

- Operational Ease: A 3 piece ball valve is suited for frequent and rapid opening and closing without friction. To fully open or close it, the lever or driving device needs to be turned to 90 degrees, which also facilitates remote operation.

- Easy Maintenance: 3 piece valves facilitate easy maintenance since the central body can be removed for servicing without removing the pipe connectors or end caps. This way, the line can continue to function without shutting down completely for maintenance. In addition, the body can be moved and welded with the trim out of the way, keeping the internal structure sound and damage-free.

Applications

Comparison Between 2 Piece Vs 3 Piece Ball Valve

From a larger perspective, both the 2 piece and 3 piece ball valves are used to completely start or stop the flow of fluids. The main point of comparison in the debate of a 3 piece vs 2 piece ball valve for a specific function lies in their design.

While a 2 piece valve is more economical as compared to a 3 piece valve, the latter can prove to be more cost-effective in the long run since it is easier to maintain. A 3 piece valve’s main design advantage is that it can be easily disassembled, and its seats and seals can be changed, while its end caps can continue functioning in the line.

Ball valves can be tightly closed with only a 90 degree rotation and a small turning torque. The completely equal valve body cavity provides a small resistance and straight flow path for the medium. It is generally believed that ball valves are most suitable for direct opening and closing use, but recent development has designed them to have throttling and flow control functions. The main characteristic of ball valves is their compact structure, easy operation and maintenance, suitable for general working media such as water, solvents, acids, and natural gas, and also suitable for harsh working conditions such as oxygen, hydrogen peroxide, methane, and ethylene. The valve body of a ball valve can be integral or modular.

Conclusion

Ball valves are among the most widely used valves and are used to completely start, stop or regulate the flow of fluids in a system. They are utilized for several commercial, industrial, and institutional purposes.

The main difference between 2 piece and 3 piece ball valves is that the latter is costlier but can be disassembled, serviced, and reassembled. Ultimately, the choice between the two boils down to budget and maintenance needs. Contact a premier valve manufacturer today to get high-quality, custom valves for specific industries.