C95800 bronze Y-type Strainer Introduction and use environment

The C95800 bronze Y-type Strainer is mainly used in seawater desalination and related fields. It is usually installed at the inlet end of the pump valve and other equipment to eliminate impurities in the medium, prevent particulate impurities from entering the channel and cause blockage to protect the equipment pipeline. The accessories are protected from wear and clogging。

Aluminum Bronze (ASTM B 148, C95800) Y-strainers are furnished standard with drain connections and pipe plugs. Most commonly, Y-strainers are fitted in the field with nipples and drain valves to permit the strainer screen to be cleaned while the system is still in process. By opening the drain valve while the system is under pressure, the debris trapped in the screen is “blown” through this connection helping to reduce system shut-downs for maintenance and cleaning.

Y-strainers are offered in both domestic and foreign castings with a wide variety of straining options for almost any application. also provides Y-strainers that meet or exceed military

The C95800 bronze Y-type Strainer is an indispensable device in the pipeline system for conveying the medium. It is usually installed at the inlet end of the pressure reducing valve, pressure relief valve, water level valve or other equipment to remove impurities in the medium to protect the normal use of valves and equipment. . The Y-type filter has the characteristics of perfect structure, small resistance and convenient sewage discharge. The applicable medium is water, oil and gas. Generally, the water distribution network is 18-30 mesh/cm2, the ventilation network is 40-100 mesh/cm2, and the oil distribution network is 100-480 mesh/cm2. Filters can be made according to user requirements. Filter prices, filter manufacturers, filter prices. The filter is an indispensable device on the conveying medium pipeline. It is usually installed at the inlet end of the pressure reducing valve, pressure relief valve, water level valve or other equipment to eliminate impurities in the medium and protect the normal operation of the valve and equipment. use. When the fluid enters the filter cartridge with a certain size filter screen, its impurities are blocked, and the clean filtrate is discharged from the filter outlet. When cleaning is required, just take out the detachable filter cartridge and reload it after processing. Yes, therefore, it is extremely convenient to use and maintain.

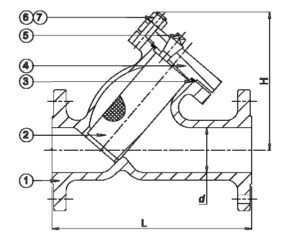

C95800 bronze Y-type Strainer Main Parts Material List

| NO | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| PARTS NAME | BODY | FLANGE | BONNET | GASKET | SCREE | BOLT | NUT | PLUG |

| PARTS MATERIAL | C95800 | C95800 | C95800 | PTFE | 2205 | 316 | 316 | 316 |

Type: DIN C95800 Y STRAINER

Size: DN40

Pressure: PN6

Body material: ASTM B148 C95800

Trim material: Monel K400

Connection ends: RF

ASME B16.34 C95800 Y Strainer, ASTM B148 C95800 Y Strainer, C95800 Y Strainer Supplier, Class 150 LB C95800 Y Strainer

Nickel Aluminum Bronze excels in many industrial processes. The followings are some of the environments where Nickel Aluminum Bronze is fully resistant to corrosion.

There are various types and types of filters. In order to achieve a good filtering effect, it is particularly important to choose which filter is more suitable. The filter is an indispensable device on the conveying medium pipeline. Pressure relief valve, fixed water level valve, the inlet end equipment of Fanggong filter and other equipment, the filter is composed of cylinder, stainless steel screen, sewage part, transmission device and electrical control part, the water to be treated passes through the filter screen. After the filter cartridge, its impurities are blocked. When cleaning is required, just take out the detachable filter cartridge and reload it after processing. Therefore, it is extremely convenient to use and maintain.

How to selection of filters is generally based on the following five principles.

1. Import and export diameter:

In principle, the inlet and outlet diameter of the filter should not be smaller than the inlet diameter of the matching pump, which is generally the same as the diameter of the inlet pipeline.

2. Nominal pressure:

Determine the pressure rating of the filter according to the possible pressure in the filter line.

3. Selection of the number of holes:

The main consideration is the particle size of impurities to be intercepted, which is determined according to the process requirements of the medium. For the particle size that can be intercepted by wire meshes of various specifications, please refer to the table “Filter Specifications”.

4. Filter material:

The material of the filter is generally the same as that of the connected process pipeline. For different service conditions, the filter of cast iron, carbon steel, low alloy steel or stainless steel can be considered.

5. Calculation of filter resistance loss:

For water filters, under the general calculation of rated flow rate, the pressure loss is 0.52 ~ 1.2kpa