Differences Between Gate And Butterfly Valves

/em Notícias da indústria /por VÁLVULA STVGATE VALVE VS. BUTTERFLY VALVE

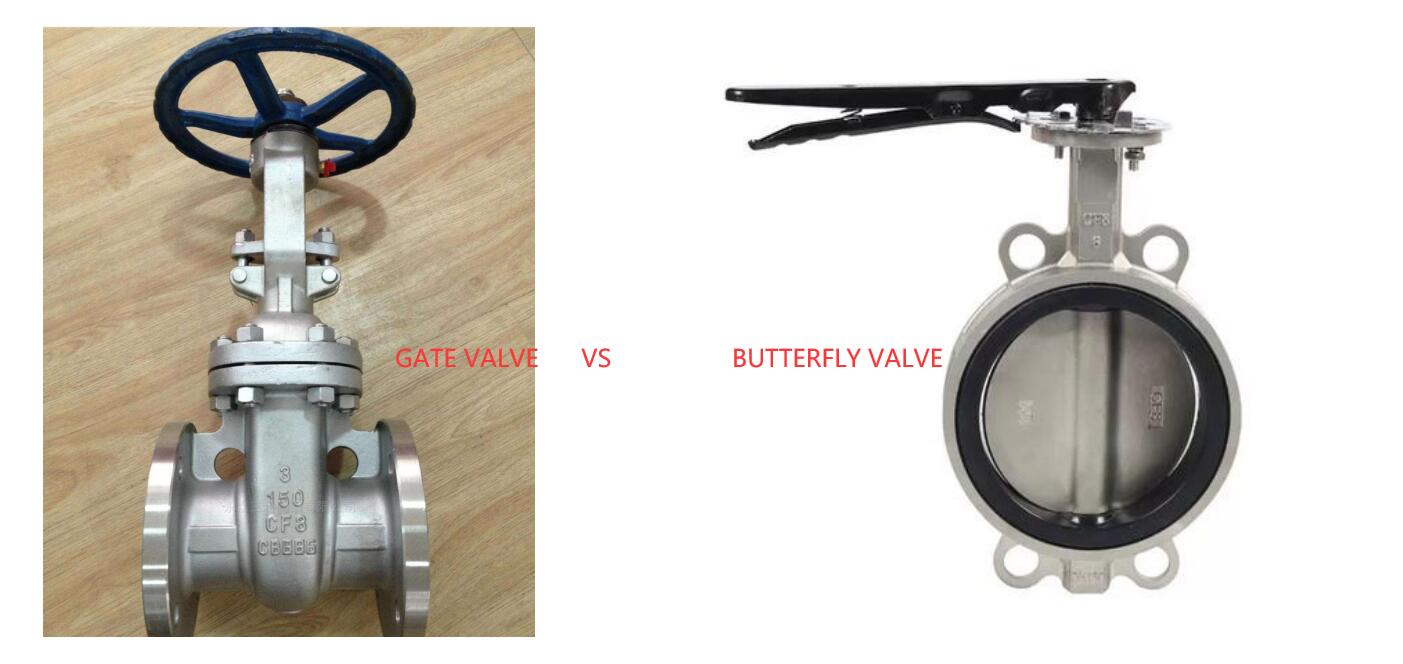

Gate valves and butterfly valves are widely utilized in various industrial and domestic piping systems for fluid control. Despite serving the purpose of regulating flow, they exhibit distinct differences in design, operation, maintenance, and application suitability.

Válvula de gaveta

Design and Operation: A gate valve features a flat gate that moves up and down in a linear motion perpendicular to the direction of flow. The valve operates by a handwheel or an actuator, and it is primarily used for starting or stopping the flow, allowing for a full, unrestricted flow path when fully open.

Vantagens:

- Provides minimal pressure drop when fully open.

- Suitable for both on/off and isolation applications.

- Can handle thick fluids, as the gate can cut through viscous flow.

Disadvantages:

- Slow to open and close due to the multiple turns required on the handwheel.

- Not suitable for throttling applications, as partial opening can cause seat and gate damage.

- Larger size compared to butterfly valves, requiring more space for installation and operation.

Válvula Borboleta

Design and Operation: A butterfly valve consists of a disc that rotates around a central axis within the body of the valve, allowing for quick and efficient flow control. Operated by a handle, gear, or actuator, butterfly valves can be used for both on/off control and throttling.

Vantagens:

- Compact and lightweight design, requiring less space and support.

- Quick to open and close, offering good control over the flow rate.

- Generally more cost-effective than gate valves, especially in larger sizes.

Disadvantages:

- The presence of the disc in the flow path can cause a pressure drop, even when fully open.

- Not ideal for applications with particulate-laden fluids, as particles can accumulate around the disc and stem, potentially leading to wear or operational issues.

- Sealing performance might not be as effective as gate valves for high-pressure applications.

Key Differences Between Gate And Butterfly Valves

- Flow Control: Gate valves are best suited for on/off applications with minimal pressure drop, while butterfly valves offer superior functionality in throttling and quick operation scenarios.

- Design and Space Requirements: Gate valves require more space due to their linear operation and larger size, making butterfly valves more suitable for compact or limited-space environments.

- Cost and Maintenance: Butterfly valves are generally more cost-effective and easier to maintain due to their simpler design and fewer moving parts. Gate valves, on the other hand, may require more maintenance, especially in systems with solid or viscous fluids.

Application Suitability Of These Two Types Of Valves

- Gate Valves: Preferred in applications where an unobstructed flow and tight shutoff are required, such as in water and wastewater treatment, oil and gas pipelines, and other high-pressure systems.

- Butterfly Valves: Ideal for applications requiring flow regulation and where space and cost are concerns, including HVAC systems, pharmaceutical processing, and food and beverage industries.

Selecting between a gate valve and a butterfly valve depends on the specific requirements of the application, including flow control needs, system pressure, space constraints, and budget considerations. Each valve type offers unique advantages that make it suitable for particular scenarios, ensuring efficient and reliable fluid control in diverse settings.