Description

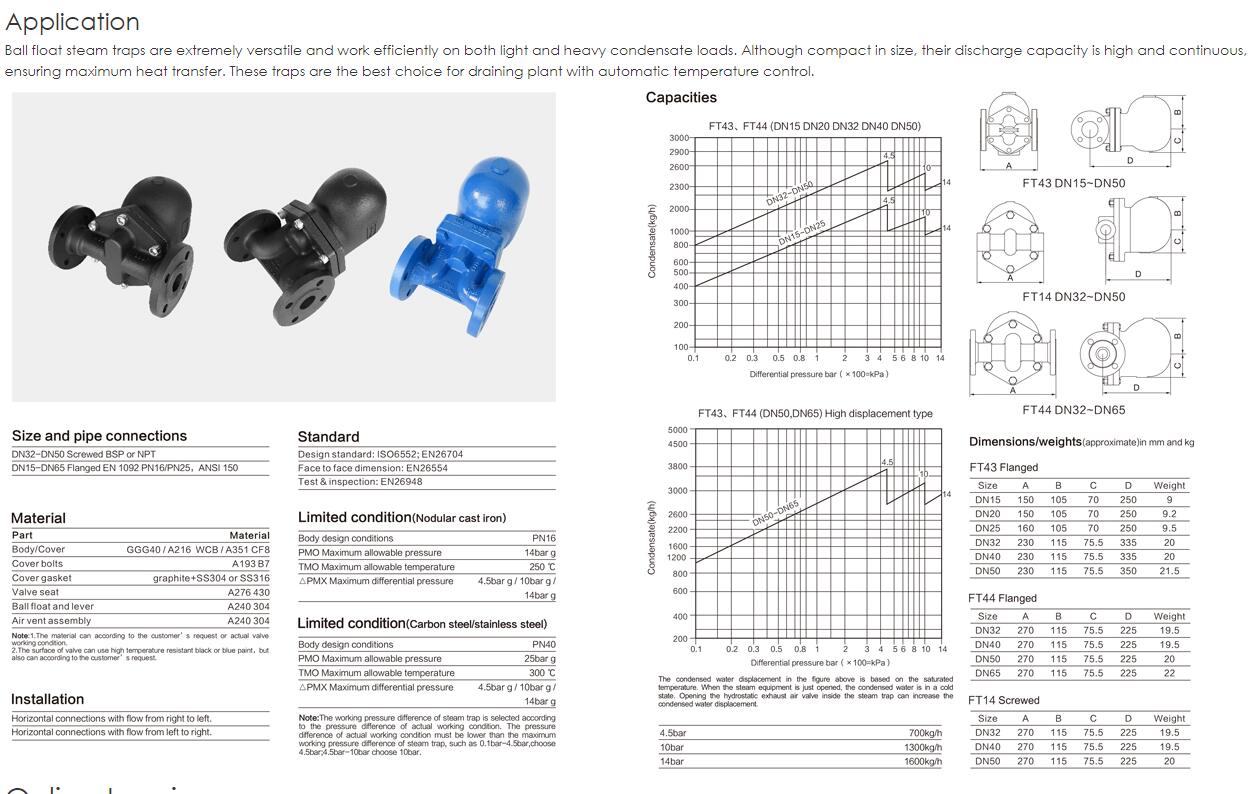

1. Carbon steel 1.0619 (WCB) steam trap.

2. Stainless steel internal parts.

3. Integral automatic air venting.

4. High durability and easy maintenance.

5. Application: Steam pipelines drainage.

6. Flanged ends according to EN 1092-1 PN16.

7. DN25: Single Seat

DN40-50: Double Seat

Working Conditions:

Horizontal installation (see the indication arrow).

See arrow of flow direction.

Body design conditions: PN16.

Maximum allowable pressure (PMA): 16 bar at 120ºC.

Maximum allowable temperature (TMA): 250ºC.

Maximum differential pressure:

Model 045: ΔP max 4,5 bar

Model 100: ΔP max 10 bar

Extensively applied in petroleum, metallurgy, chemical industry, paper making, foods and steam equipments, driers and large heat exchangers, especially for working

places with large amount of condensed water to be discharged.

Advantage

1. Two balanced valve bases increase the area of flux and acquire large amount of discharged water.

2. Automatic gas discharging mixture inside can discharge the gas in time while rapidly opening the equipment.

3. Stainless steel structures provide perfect performances of anti-corruption.