Knife Gate Valve Dimensions

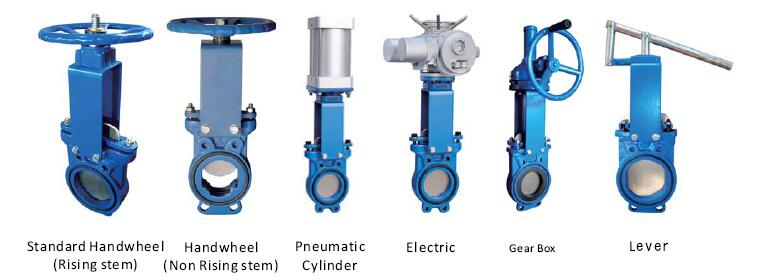

Knife Gate Valve Dimensions vary depending on the valve size, pressure rating, design standards, and manufacturer. Below is a general guide to common dimensions and specifications:

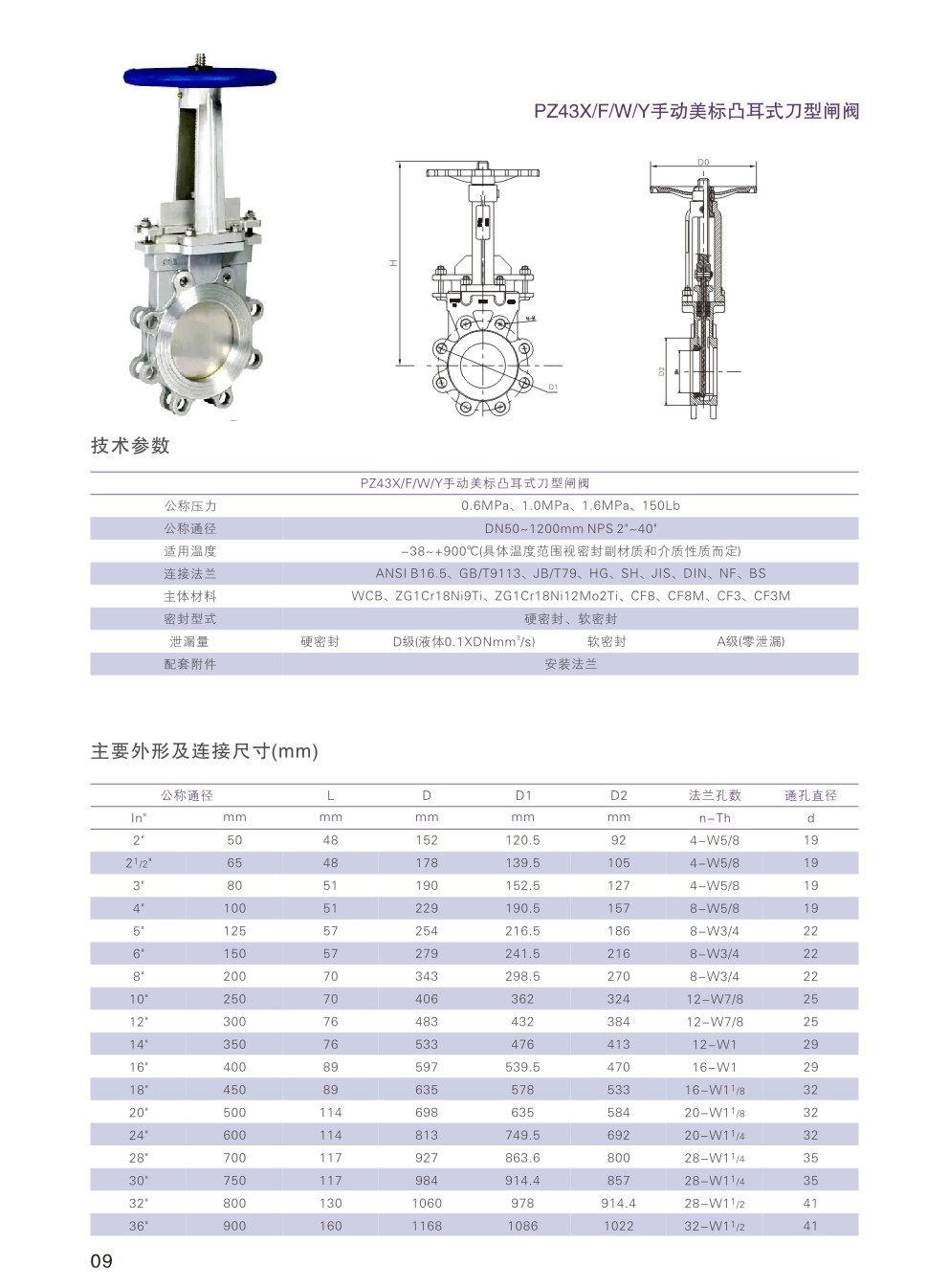

1. Standard Sizes

Knife gate valves are typically available in sizes ranging from:

- DN50 to DN1800 (2″ to 72″) for industrial applications.

- Smaller sizes (e.g., 2″–24″) are more common for general use, while larger sizes (36″–72″) are used in mining, pulp/paper, or wastewater systems.

2. Key Dimensions

Face-to-Face Length

- Follows standards like ANSI B16.10 or ISO 5752 for flange spacing.

- Example (ANSI Class 150):

- 2″: 178 mm (7″)

- 12″: 610 mm (24″)

- 24″: 940 mm (37″)

Flange Dimensions

- Flange standards: ANSI B16.5 (ASME), EN 1092-1 (DIN), or JIS.

- Example for ANSI Class 150 Flange (2″):

- Flange OD: 152 mm (6″)

- Bolt Circle Diameter: 121 mm (4.75″)

- Bolt Holes: 4 x 19 mm (0.75″)

Body Thickness

- Depends on pressure rating and material (e.g., cast iron, stainless steel).

- Higher pressure ratings (e.g., Class 300) require thicker bodies.

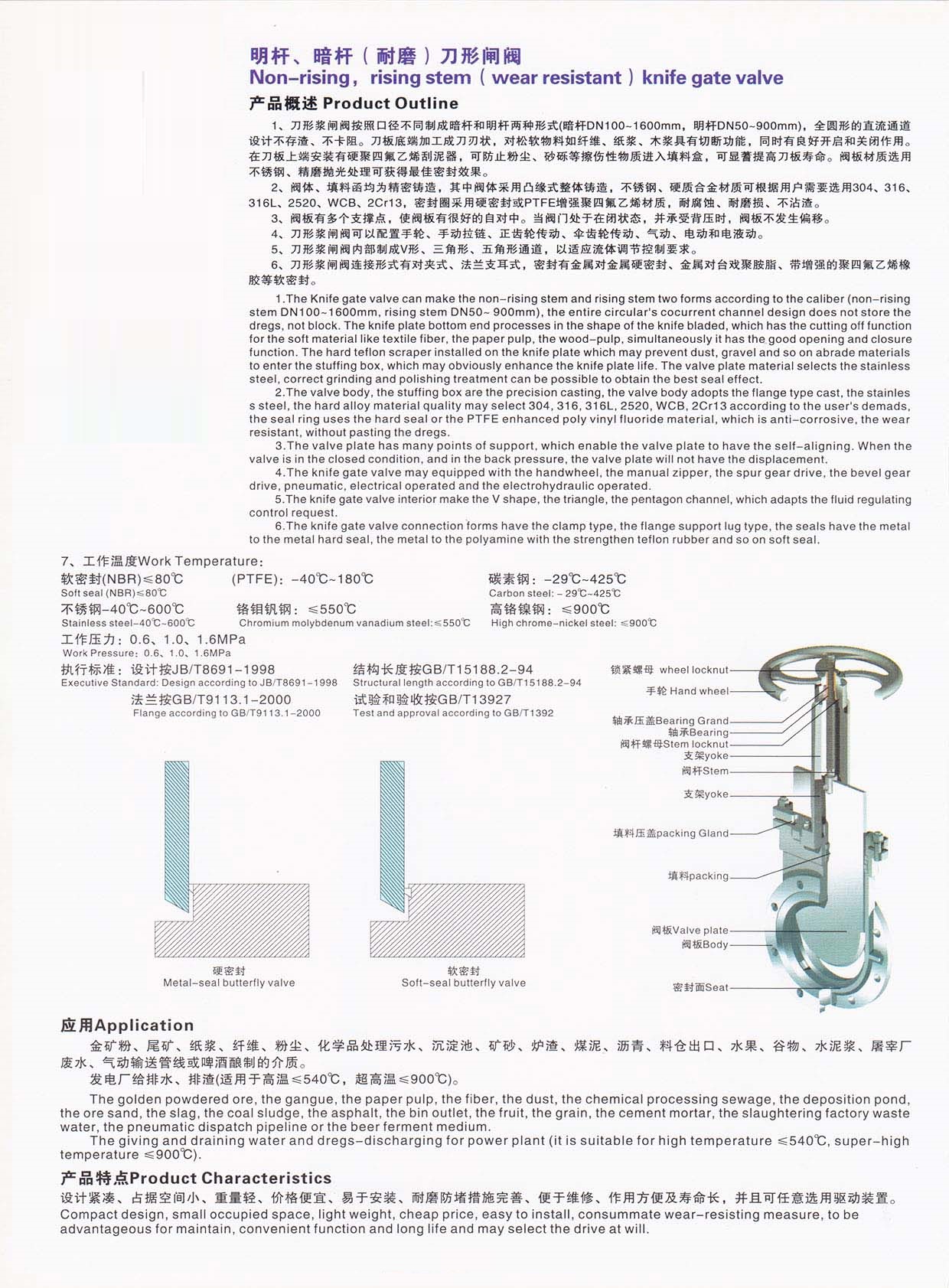

3. Pressure Ratings

- Common ratings: ANSI Class 150, Class 300, or PN10/PN16 (European standards).

- Higher pressure classes increase valve weight and dimensions.

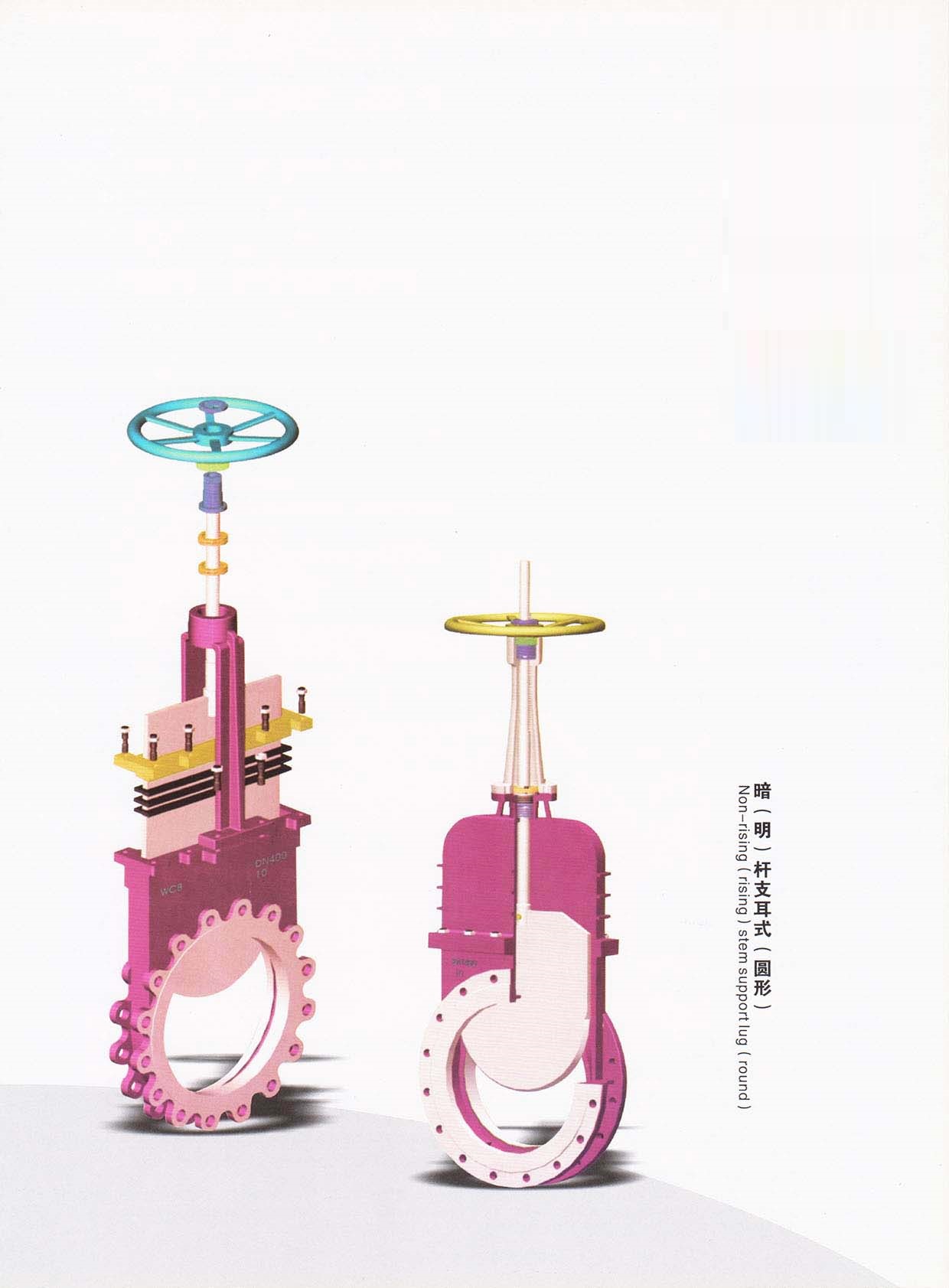

4. End Connections

- Wafer Type: Compact design, fits between pipeline flanges.

- Lug Type: Threaded inserts for bolt connections (ideal for dead-end service).

- Flanged Ends: Directly bolted to pipeline flanges (common for larger sizes).

5. Example Dimensions Table

| Valve Size (DN) | Face-to-Face (mm) | Flange OD (mm) | Weight (kg) |

|---|---|---|---|

| 50 (2″) | 178 | 152 | 5–8 |

| 150 (6″) | 403 | 279 | 25–35 |

| 300 (12″) | 610 | 514 | 120–150 |

| 600 (24″) | 940 | 775 | 400–500 |

6. Installation Considerations

- Ensure adequate clearance for gate movement and maintenance.

- Check pipeline alignment to avoid stress on the valve body.

- For slurry applications, opt for valves with wider bodies to reduce clogging.

7. Standards

- API 6D: Specifies requirements for pipeline valves.

- MSS SP-81: Standard for knife gate valves.

- API598: Industrial valve testing.

Important Notes

- Dimensions vary slightly between manufacturers (e.g., DeZURIK, ITT Engineered Valves, Velan).

- Custom valves may have non-standard dimensions for specific applications.

- Always consult the manufacturer’s datasheet for precise measurements.

For exact dimensions, refer to the STV valve’s technical drawings or contact the STV Valve sales team directly.

Flange Dimensions Flange standards: ANSI B16.5 (ASME), EN 1092-1 (DIN), or JIS. Example for ANSI Class 150 Flange (2″): Flange OD: 152 mm (6″) Bolt Circle Diameter: 121 mm (4.75″) Bolt Holes: 4 x 19 mm (0.75″)

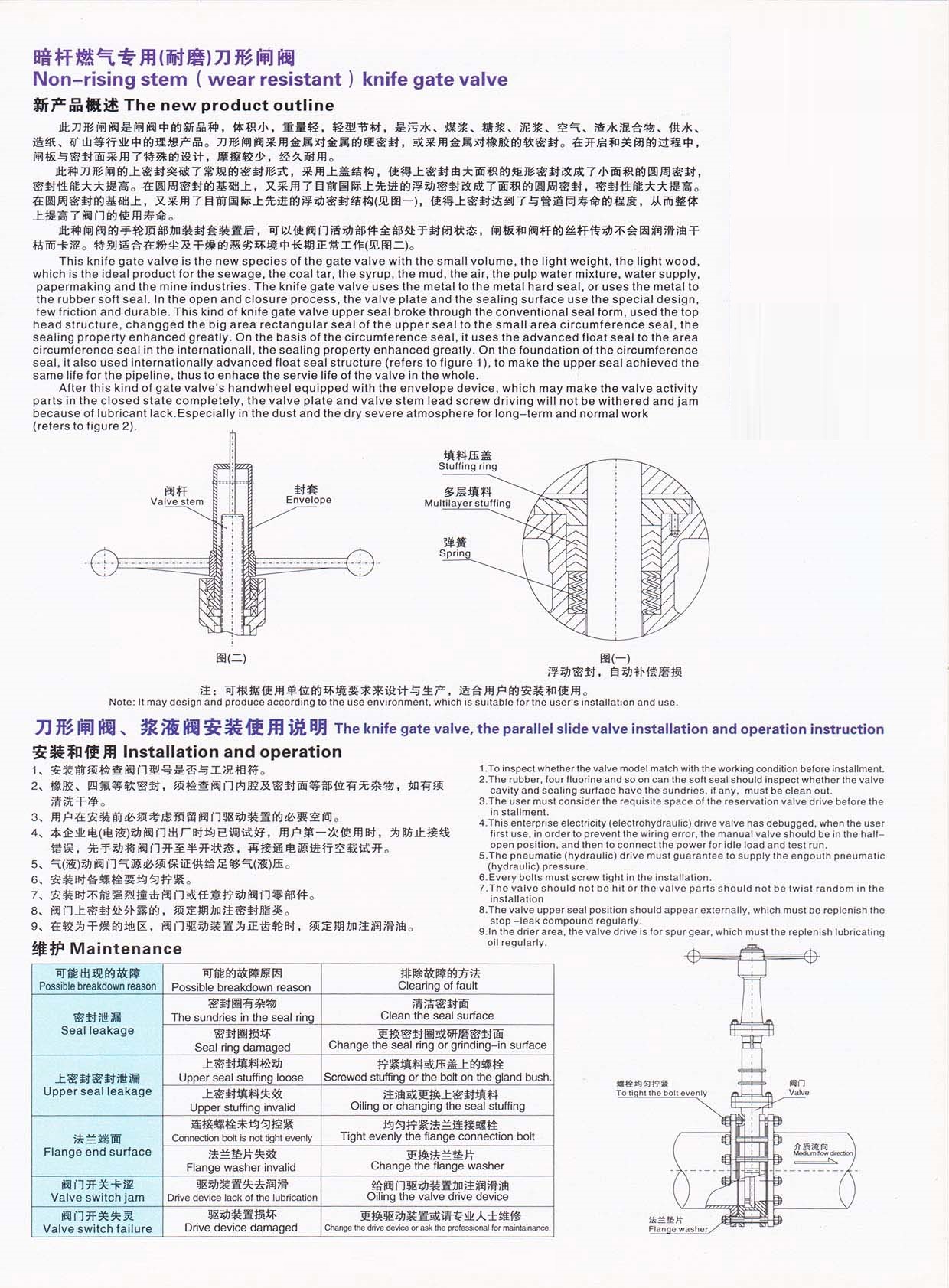

Knife gate valves are a specific type of isolation valve that is typically used for media that are not hazardous such as wastewater. The bore of a knife gate valve is full and smooth so the use of a cleaning pig for maintenance is possible. While there is no pressure loss across the valve, they are susceptible to “chatter” or vibration during opening or closing caused by fluid flow against the gate. This is not a significant issue as the appropriate application for a knife gate valve is isolation, not flow restriction, so the normal operating position is fully open or fully closed. A thin (typically) stainless-steel gate is raised and lowered into the bore by a spindle or rising screw and, unlike other gate valves, lifts outside of the valve body when raised. The guide and seal are located around the circumference of the bore and provide a bi-directional, bubble-tight seal.