8 Different Types of Check Valves and Their Applications

8 Different Types of Check Valves and Their Applications

A check valve refers to a type of valve whose opening and closing components are circular valve discs that act by their own weight and medium pressure to block medium backflow. It belongs to the category of automatic valves, also known as check valves, one-way valves, return valves or isolation valves. There are several common types of check valves.

While it might seem like a simple piece, there are various types of check valves, each designed for specific needs and applications. In this guide, we will walk you through eight different types of check valves, helping you understand their unique functions and where they are most effectively used.

Types of Backflow Valves and Ways to Choose

The significance of backflow valves cannot be overstated in the intricate domain of fluid control systems. These specialized valves serve as a protective barrier against the undesirable reversal of fluid flow, thereby ensuring the integrity and safety of the entire system.

The choice of a backflow valve is not merely a matter of plug-and-play, it demands a nuanced understanding of the operational requirements of your system, fluid dynamics, and potential risk factors.

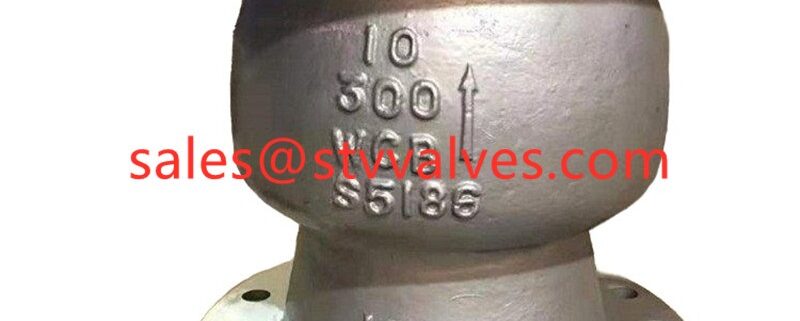

1. Lift Check Valves

Among check valves, the lift check valve stands as a paragon of efficiency and versatility, particularly in high-pressure environments. Characterized by a guided disc and a seating arrangement akin to globe valves, this valve type offers three distinct body patterns—horizontal, angle, and vertical.

The disc, often shaped as a piston or ball, is lifted by the upward flow, allowing fluid passage. Gravity and backflow synergistically force the disc to seal the seat upon flow cessation or reversal, thereby preventing backflow. Notably, lift check valves are prevalent in high-rise buildings, industrial plants, and water treatment facilities, offering a blend of reliability and economic viability.

2. Piston Check Valves

DIN Piston Type Lift Check Valve,Din Lift Check Valve,Lift Check Valve DIN PN250,Cast Steel Lift Check,DIN 3845 Lift Check Valve,BW Lift Check Valve,DN125 Lift Check Valve

The piston check valve, also known as a plug check valve, epitomizes precision control in fluid management systems. This valve type offers an extra layer of security through an optional spring mechanism, operating through the linear motion of a piston within the valve chamber.

The spring ensures the valve remains closed when not actively engaged, minimizing the risk of accidental backflow. The piston’s design and the spring’s tension are meticulously calibrated to respond to specific flow pressures, making this valve type highly adaptable.

Piston check valves are commonly employed in systems requiring rapid flow changes and offer a robust solution for maintaining unidirectional fluid flow.

3. Ball Check Valves

China Válvula de retención tipo bola de acero forjado, válvula de retención de bola 316, válvula de retención de bola DN 50, válvula de retención de bola con extremo SW, válvula de retención de bola de acero forjado, válvula de retención de bola API 602, válvula de retención de bola de 2 pulgadas, proveedor de válvula de retención de bola A105

The ball check valve operates on a principle of elegant simplicity, utilizing gravity as its primary control mechanism. A ball is strategically positioned within the valve chamber to obstruct or permit fluid flow. The ball is lifted when the system pressure escalates, allowing unidirectional flow.

Conversely, gravity pulls the ball back into its seat as the pressure diminishes, effectively sealing the system against reverse flow. This type of check valve offers a broad spectrum of material and style options, making it versatile for various applications. Renowned for its low maintenance and high reliability, the ball check valve is indispensable in fluid control systems.

4. Swing Check Valves

The swing check valve serves as an example of automated efficiency in fluid control systems. This valve type, employing an internal disc, capitalizes on fluid pressure to regulate flow.

As fluid courses through the system in the intended direction, the pressure propels the disc to open, facilitating flow. Conversely, when the pressure wanes, the disc swings back into its closed position, thwarting any potential backflow.

Particularly well-suited for applications with high solid content and fewer on/off cycles, swing check valves offer a cost-effective solution without compromising performance. Their automatic operation eliminates the need for external power, making them an eco-conscious choice.

5. Spring-Loaded Check Valves

The spring-loaded check valve is a paragon of precision engineering designed to preemptively thwart backflow and mitigate hydraulic shock, commonly known as water hammer.

This valve type incorporates a spring mechanism that assists in its rapid closure, ensuring the valve shuts before fluid flow reverses. The spring-loaded design allows for installation in any orientation, offering unparalleled flexibility.

Whether in-line or Y-shaped configuration, the valve’s spring ensures a secure seal, making it an indispensable asset in fluid process systems. For those searching for a valve that offers both reliability and adaptability, the spring-loaded check valve is the epitome of fluid control excellence.

6. Wafer Check Valves

2205 Dual Plate Wafer Check Valve Supplier In China, 300LB Wafer Check Valve, Rised Face Flanged Dual Plate Wafer Check Valve,2205 Dual Plate Wafer Check Valve Manufacture

The wafer check valve is a compact powerhouse, ingeniously designed with two half-circle disks that fold together to allow forward flow and retract to prevent backflow. This valve’s slim profile makes it an ideal choice for systems where space is premium.

Despite its minimalistic design, the wafer check valve offers robust performance, operating efficiently even at low-pressure differentials. Its unique construction allows it to fit snugly between a set of flanges, providing a secure seal without the bulk of traditional check valves. The wafer check valve is a prime choice if you seek a streamlined yet highly effective valve solution.

7. Tilting Disc Check Valves

Tilting Disc Check Valves: Tilting disc check valves utilize a disc that tilts away from the seat to allow forward flow and returns to the closed position to prevent backflow. They offer low-pressure drop and are suitable for applications with high flow velocities, such as water distribution systems, sewage treatment plants, and firefighting systems.

8.Y Type Check Valves

This is a check valve which is a modification of a standard check valve in which the valve disc/ball is mounted at an angle to the axis of the pipe. This angle of the disc to the pipe creates a valve of Y-shape. As such, it was named the “Y-check valve”. This type of valve is used to prevent fluid from reversing in the piping system. The flow of fluid in the reverse direction happens when the pump turns off or when there is a backflow of fluid. Preventing reverse fluid flow is very important since it helps to prevent contamination in applications like foods and water as well as prevent damage to equipment like boilers and pumps. Y-check valve manufacturers design various types of these valves with certain material properties making them suitable for use in a specific area of application. The valve in the market will have a user manual from the Y-check valve manufacturer illustrating how the valve can be used and also working parameters such as temperature, pressure, and velocity among others. Following such parameters from the check valve manufacturer helps the valve serve for a long period

Each type of check valve has its advantages and is best suited to specific applications and operating conditions. Understanding the differences between these types of valves is essential for selecting the most suitable option for your system. Whether you need a simple swing check valve for basic flow control or a specialized diaphragm check valve for precise sealing, there’s a check valve to meet your needs. Sanitary Fittings is happy to offer an assortment of check valves and replacement parts.