DIFFERENCES BETWEEN DOUBLE VS. TRIPLE ECCENTRIC BUTTERFLY VALVE

- Double and triple eccentric butterfly valves are both designed to offer improved performance over traditional concentric butterfly valves, especially in high-pressure and high-temperature applications. The terms “double” and “triple” refer to the number of offsets (eccentricities) in the valve design, which significantly affect how the valve operates and seals. Understanding the differences between these two types of eccentric butterfly valves is crucial for selecting the right valve for specific operational needs.

Double Eccentric Butterfly Valves (Double Offset)

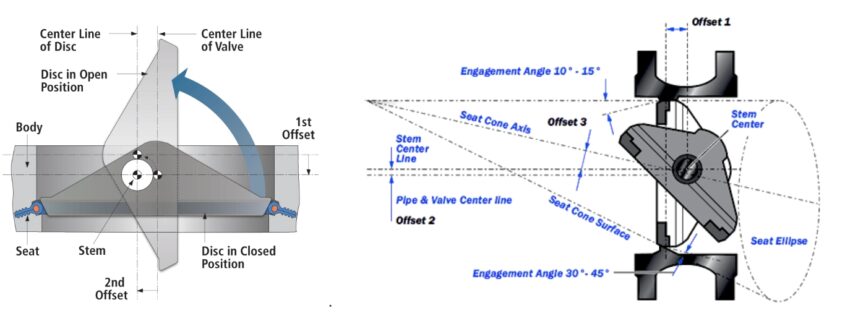

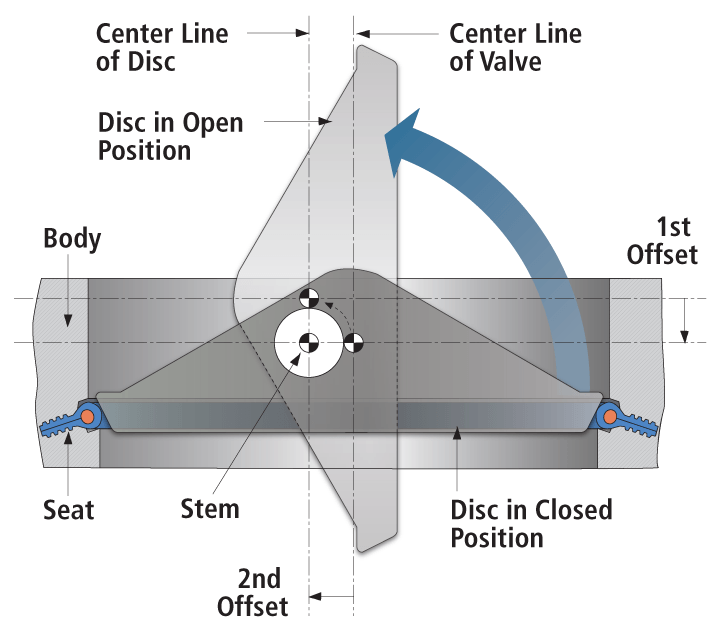

- Design: The first offset is the shaft placement off the pipe or disc centerline, which allows the disc to move off the seat upon opening, reducing wear on the sealing surface. The second offset is the shaft placement behind the disc plane, creating a cam action during operation that enhances sealing capability and reduces operating torque.

- Sealing: Typically utilizes a resilient (soft) seat, which can be made of materials like PTFE, rubber, or other polymers, allowing for tight shut-off in various applications.

- Anwendungen: Suitable for higher pressure and temperature applications than concentric valves but below the extreme conditions that triple offset valves are designed for. Commonly used in water distribution, HVAC systems, light industrial processes, and chemical applications where a tight seal and durability are required.

Triple Eccentric Butterfly Valves (Triple Offset)

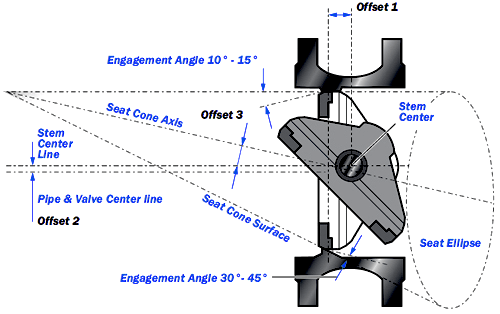

- Design: Incorporates three offsets: two similar to the double eccentric design and a third offset, which involves angling the conical shape of the seating surface. This geometry ensures that the disc only contacts the seat at the final point of closure, minimizing wear and allowing for a metal-to-metal seal.

- Sealing: The metal-to-metal seat design enables the triple offset valve to handle extreme temperatures, pressures, and corrosive media, providing a long-lasting, bubble-tight seal.

- Anwendungen: Engineered for the most demanding applications, including high-pressure steam, oil and gas pipelines, power generation, and process industries where reliability and performance under extreme conditions are paramount.

Key Differences (Double/Triple Eccentric Types)

- Sealing Mechanism: Double eccentric valves usually have resilient seats for good sealing at lower pressures and temperatures, while triple eccentric valves use a metal-to-metal seat design for harsh conditions.

- Wear and Tear: Triple offset valves minimize wear on the sealing surfaces due to the disc only making contact at full closure, unlike double offset valves, which may experience more wear due to their soft sealing materials.

- Application Suitability: Double offset valves are versatile for a wide range of applications but might not be suitable for the highest pressures and temperatures. Triple offset valves are designed for extreme conditions where performance and durability are critical.

In summary, the choice between double and triple eccentric butterfly valves depends on the specific application requirements, including pressure, temperature, and the nature of the media being handled. Triple offset valves are typically chosen for their ability to perform in extreme conditions, offering durability and a reliable seal, whereas double offset valves provide an efficient and cost-effective solution for a broad range of less severe applications.

.

.  The images show the design difference between a double and a triple eccentric butterfly valve (respectively at the left and right side of the diagram).

The images show the design difference between a double and a triple eccentric butterfly valve (respectively at the left and right side of the diagram).MATERIALS FOR BUTTERFLY VALVES