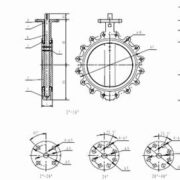

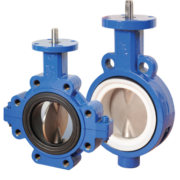

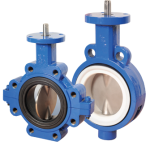

We just delivered many butterfly Valve to one of our major customers in the Singpore.

All valves are painted, and their min thickness is 150 microns.

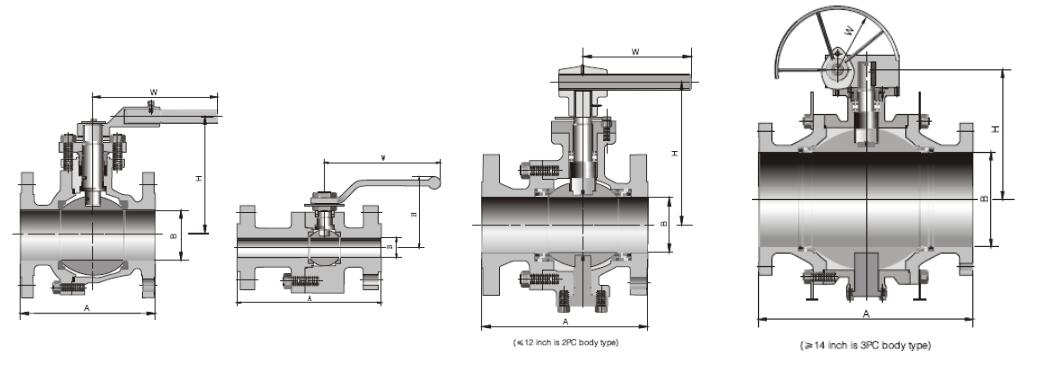

Description:

API 609 LUG BUTTERFLY VALVE, PTFE Seat

Design and Manufacture:API 609

Face to Face Dimension:API609,ISO5752,ASME B16.10

Flange Connection Dimension:ASME B16.5,ASME B16.47

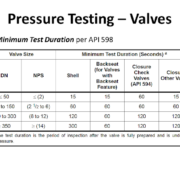

Test and Inspection:API 598

Pressure Temperature Rating:API 609,ASME B16.34

Product Range

Body material:Cast Steel,Stainless Steel,Monel

Nominal diameter:2″~120″(DN50~DN3000)

End Connection: Double Flange,Wafer,Lug,etc

Pressure range: Class150 ~ 600(PN16~PN100)

Working temperature:-46℃ ~ +550℃

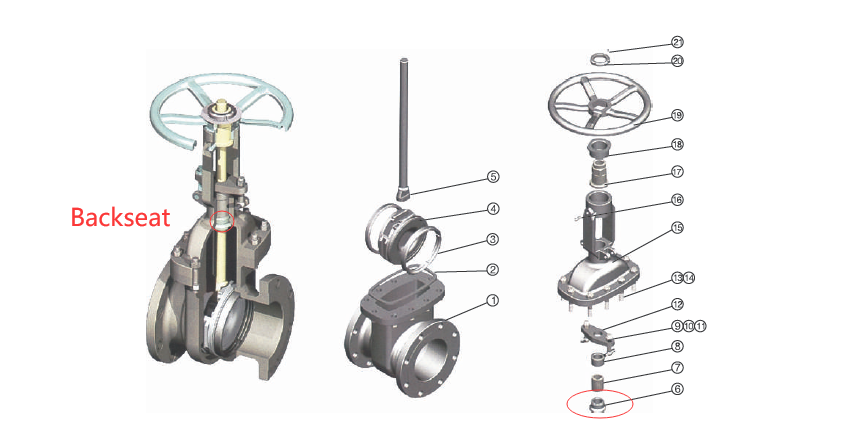

Material:

Body: WCB

Disc:WCB

Stem: F6

Seat: PTFE

Size:DN150

Stud/Nut:A193 B7/ A194 2H

pneumatic butterfly valve,wafer butterfly valve,lug butterfly valve,triple offset butterfly valve,4 inch butterfly valve,6 inch butterfly valve

STV Valve Technology Group Co., Ltd is a professional leader China stainless steel butterfly valve,double eccentric butterfly valve,flanged butterfly valve,flanged butterfly valve,pneumatic butterfly valve,wafer butterfly valve,lug butterfly valve,triple offset butterfly valve,4 inch butterfly valve,6 inch butterfly valve,3 inch butterfly valve,8 inch butterfly valve,2 inch butterfly valve Manufacture with high quality and competitive price

Both lug and wafer butterfly valves are used in a number of applications for industrial sectors that include food processing, pharmaceutical, chemical, oil, water as well as waste water management. The valves utilized in these industries are generally manufactured in compliance with the “Pharmaceutical Quality/Manufacturing Standard”, cGMP (current good manufacturing practice) guidelines. Butterfly valves for the most part have replaced ball valves in a lot of industries. This is especially the case for those dealing with petroleum because of they are less expensive and easy to install. It’s important to note that pipelines that contain butterfly valves can’t be ‘pigged’ for cleaning. “Pigging” is the process of making use of devices referred to as “pigs” to carry out a variety of maintenance operations.

Both lug and wafer butterfly valves are used in a number of applications for industrial sectors that include food processing, pharmaceutical, chemical, oil, water as well as waste water management. The valves utilized in these industries are generally manufactured in compliance with the “Pharmaceutical Quality/Manufacturing Standard”, cGMP (current good manufacturing practice) guidelines. Butterfly valves for the most part have replaced ball valves in a lot of industries. This is especially the case for those dealing with petroleum because of they are less expensive and easy to install. It’s important to note that pipelines that contain butterfly valves can’t be ‘pigged’ for cleaning. “Pigging” is the process of making use of devices referred to as “pigs” to carry out a variety of maintenance operations.