STV Valve delivery 600LB CF3 GATE VALVE

10PCS 10″ 600LB Flanged 316L (CF3) Gate Valves, 316L Trim, Lever Op and 20pcs 8″ 150LB 316 Ball Valves with Worm Gear

Get in touch and give us your valve challenge.

Cost Effective and quick solutions.

Read news issued by STV Valve Company and acquire more comprehensive information about Company, latest valves and valve industry progress

10PCS 10″ 600LB Flanged 316L (CF3) Gate Valves, 316L Trim, Lever Op and 20pcs 8″ 150LB 316 Ball Valves with Worm Gear

Get in touch and give us your valve challenge.

Cost Effective and quick solutions.

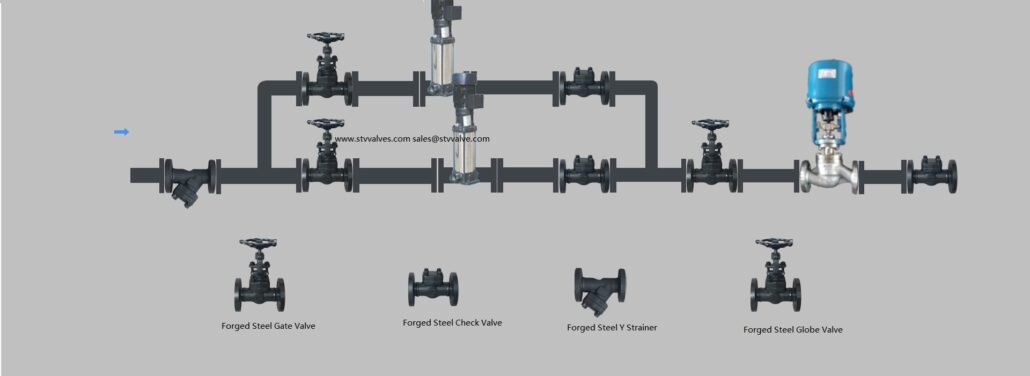

Forged steel gate valve is mainly used to cut off or connect the medium in the pipeline, not for regulating or throttling. According to different methods, gate valve can be divided into parallel gate valve, wedge gate valve, lifting gate valve, rotary rod gate valve, quick opening and closing gate valve, necking gate valve, flat gate valve, etc.

For stainless steel gate valves, the valve is disconnected from the valve stem and the spool due to corrosion, wear or improper operation during opening and closing. After the valve is closed, it cannot be opened. It can only be replaced after it is cut out from the system. If it cannot be cut out from the system, only another process or device will be shut down.

When the stainless steel gate valve spool is detached and cannot be cut out, the valve cover, the valve stem, the bushing and the packing can be changed without changing the valve body, the valve core and the valve seat while the sealed medium is sealed. After the gland is assembled, the valve core is exposed, and the valve stem is reconnected to the valve core by a conventional method, so that the three seals of the valve can be continuously maintained and the valve can be reopened. After the valve cover of the stainless steel gate valve is disassembled, except for the special valve, the wedge angle of the valve spool is in the friction angle range. No matter how the pressure on both ends of the valve core changes, the valve core will not be squeezed out from the valve seat under the self-locking condition. For flat valve spools, there is no more extrusion.

There are many kinds of stainless steel ball valves, each of which has different uses. When choosing ball valves, we should know what kind of Ball Valves we need. Ball valve is essential, and there will be some leakage problems such as failure. Today I will tell you the reasons for the leakage of ball valve.

Causes of internal leakage

1. The casting quality of iron castings is not high, and there are sand holes, loose structures, slag inclusions and other defects on the valve body and bonnet body.

2. The bolt is loose due to thermal shock, and the pre tightening force of the bolt is not good. Or the nonuniformity of bolt is higher than that of flange.

3. The contact between gasket and flange becomes weak due to aging failure or mechanical vibration. Touch surface with low precision (with grooves, ridges, etc.) and medium

4. Poor welding, slag inclusion, no welding, stress crack and other defects

5. The cast iron valve is damaged after being hit by heavy objects.

External leakage cause

1. The packing is not selected correctly, is not resistant to medium corrosion, and is not resistant to the use of high pressure or vacuum, high temperature or low temperature of the valve.

2. The filler has aged and lost elasticity after the service life.

3. The number of packing rings is insufficient, and the gland is not pressed tightly.

4. The gland is skewed, and the gap between the gland and the valve rod is too small or too large, which causes the valve rod to wear.

5. Improper operation and excessive force

Everyone knows that there are many types of ball valves, including this butterfly valve. Then the well-known difference between a ball valve and a butterfly valve is its opening and closing member. The opening and closing member of the butterfly valve is a block plate, and the ball valve is a ball. They all rotate around one axis of their own. Let’s continue to see what is the difference between a butterfly valve and a ball valve.

Comparison between butterfly valve and ball valve

Advantages of butterfly valve 1: simple structure, small volume and light weight; disadvantages are that the range of using pressure and working temperature is much smaller than that of ball valve

Advantages of butterfly valve 2: good sealing can be realized under low pressure; the disadvantage is that the sealing performance is much worse than that of ball valve

Advantages of butterfly valve 3: it can transport mud with the least liquid accumulated in the pipe mouth, which is better than the ball valve

Advantages of butterfly valve 4: the structural principle of butterfly valve is more suitable for making large-diameter valve, widely used in oil, gas, chemical industry and other industries

Difference one

The cut-off method of ball valve and butterfly valve is different: the ball valve blocks the passage through the ball to realize the pipe cut-off flow; the butterfly valve relies on the butterfly wing, so the pipe will not flow if it is spread and sealed.

Difference two

The structure of the ball valve is different from that of the butterfly valve: the ball valve is composed of the valve body, valve core and valve rod assembly, and the body can only see some parts; the butterfly valve is composed of the valve body, valve seat, valve plate and valve rod, and all the accessories are exposed outside. Therefore, the tightness of butterfly valve is not as good as that of ball valve. When it comes to sealing, butterfly valves are also divided into soft sealing and hard sealing. Butterfly valve structure is relatively simple, can only be used in low-pressure environment, the highest pressure is only 64 kg. Compared with the ball valve, the maximum ball valve can reach about 100 kg.

Difference three

The working principle of the ball valve and butterfly valve is different: the ball valve has a 90 degree rotation action, only because its opening and closing parts are a ball, only need to operate 90 degree rotation to achieve opening or closing, which is most suitable for switching. But now v-ball valve can be used to regulate or control the flow. Butterfly valve is a kind of valve that uses disc type opening and closing parts to turn back and forth about 90 ° to open, close or regulate medium flow. It has a good function of regulating flow and is one of the fastest-growing valve varieties.

Not all forged steel valves are black, such as stainless steel forged steel valves will not be black. You may refer to a forged steel valve made of A105 material, which is phosphatized and blackened for rust prevention. Generally, the forged steel valve of A105 material is generally phosphating black.

Hard-sealed ball valves are also a type of wear-resistant ball valves. Today we will talk about the calculation of the torque of hard-sealed ball valves. The torque of the hard-sealed ball valve is also smaller than that of a soft seal such as F4 (fluoroplastic). Generally, the torque of a metal hard-sealed ball valve is more than twice that of a soft seal. And if it is designed or used improperly, it will be stuck. The advantage of a hard-sealed ball valve over a soft-sealed ball valve is that it can be used at high temperatures or where wear is required.

The pressure hard seal ball valve is under load. The higher the pressure, the larger the load and the more laborious the operation, that is, the greater the operating torque. Factors affecting the torque of the hard-sealed ball valve are the pressure (load), the friction of the moving pair, the packing friction of the bonnet stuffing box, the machining accuracy of the rotating parts, the degree of lubrication, the pre-tightening force of the threaded joint, and the valve stem. Deformation, because the frictional force of the partial area between the valve stem and the cover rises linearly, the operating torque will increase sharply, and even the valve stem can not move directly. If the pneumatic actuator and the electric actuator do not have measures to deal with the fault, it is easy to cause Pneumatic actuators and electric actuators are damaged.

The torque calculation of the valve is specifically: the square of the valve diameter of the one-half of the valve is 3.14, which is the area of the valve plate, and multiplied by the pressure (ie the working pressure of the valve) to obtain the static pressure of the shaft, multiplied by the friction coefficient. (To check the table, the friction coefficient of general steel is 0.1, the friction coefficient of steel to rubber is 0.15), multiplied by the shaft diameter divided by 1000 to obtain the torque of the valve, the unit is cattle·meter. STV valve engineers recommend that the driving torque of the floating ball valve and the fixed ball valve drive device is at least 1.3 times the operating torque of the valve. The operating torque of the metal hard seal floating ball valve is about 4 times that of the soft seal floating ball valve. The metal hard seal is fixed. The operating torque of the ball valve is approximately 3-4 times the operating torque of the soft seal fixed ball valve.

The forged steel check valve is a pressure self-tightening valve cover. The valve designed according to this design form has a valve body and a valve cover which are screwed, and the internal pressure is sealed by a self-sealing ring. The optional sealing discs are available in swing type, lift type, and ball type. The connection standard can be American or GB threaded, welded and flanged.

Design and manufacture conform to BS5351,MSS SP-118

Connection ends conform to:

1.Socket welded ends conform to ANSI B16.11

2.Screw ends conform to ANSI B1.20.1

3.Butt-welded ends conform to ANSI B16.25

4.Flange ends conform to ANSI B16.5

5.Test and inspection conform to :API 598

Structure features:

Bolted bonnet,Welded bonnet,Pressure seal bonnet

Forged Steel,Piston,Ball or Swing type

Integral Body Seat for Piston and Ball Check valves

Separated Seat Ring design for swing check valves

Spiral Wound Gasket or Oval Ring Joint gasket

Reduced Bore or Full Port,

T-Pattern or Y-Pattern,

Product Range

Body material: A105,LF2,F5,F11,F22,304,304L,316,316L,F51,F91,20#,Inconel .Ect

Nominal diameter:1/2″~2″(DN15~DN50)

End Connection: THR,SW,BW,RF,RTJ

Working temperature: -196℃~+560℃

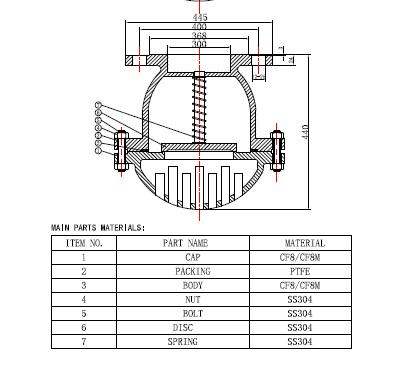

The Foot valve consists of valve evaluation, disc, bonnet, bushing, sealing ring and other parts. See the water from the water source in the figure below from the bonnet to the valve body. Under the action of fluid pressure, the valve disc opens water.

When the pressure in the outlet pipe closes the valve disc rapidly after stop, the liquid will not be poured back to the water source, which plays the role of unblocked pumping and saving water energy loss.

“5 Key Things You Didn’t Know About Wafer Ball Valves – Explained!”

Wafer ball valve is a common industrial valve consisting of a spherical valve core and a valve body. It can control the flow of fluid by rotating the valve core. When the valve core rotates 90 degrees, the channel on the sphere aligns with the channel on the valve body, allowing fluid to pass through; After rotating 90 degrees, the channels are misaligned and the fluid cannot pass through

1.The valve plates of clamp ball valves and flange gate valves are installed in the diameter direction of the pipeline. In the cylindrical passage of the valve body, the disc-shaped valve plate rotates around the axis at an angle between 0 ° and 90 °. When it rotates to 90 °, the valve is fully open. This valve is generally installed horizontally.

2.When the ball valve is in the fully open position, the thickness of the valve plate is the resistance of the medium flowing through the valve body, so the pressure drop generated by this valve is very small, thus it has good flow control characteristics. There are two types of sealing for tower valves: elastic sealing and metal sealing. Elastic sealing valve, the sealing ring can be embedded on the valve body or attached around the valve plate.

3.Valves with metal seals generally have a longer lifespan than those with elastic seals, but it is difficult to achieve complete sealing. Metal seals can adapt to higher operating temperatures, while elastic seals have the drawback of being limited by temperature.

4.If a ball valve is required for flow control, the main thing is to choose the correct size and type of valve. The structural principle of ball valves is particularly suitable for making large-diameter valves. Ball valves are not only widely used in general industries such as petroleum, gas, chemical, and water treatment, but also in the cooling water system of thermal power plants.

5.There are two commonly used types of ball valves: clamp ball valves and flange ball valves. Clamp on ball valves are connected between two pipeline flanges using double headed bolts. Flange ball valves have flanges on the valve and are connected to the pipeline flanges at both ends using bolts.