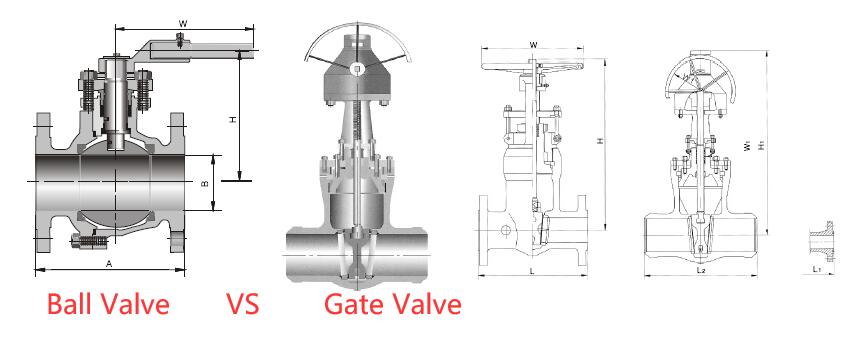

Which is better gate valve or ball valve

In real life, there are many valve products, but the most common valves are ball valves and gate valves, which are also used the most. However, for people who buy ball valves and gate valves, we will know what kind of use and function they have, as well as the difference between them, and how to choose high-quality ball valves and gate valves before buying. To this end, we have summarized some knowledge about ball valves and gate valves. Let me tell you Which is better gate valve or ball valve?

Which is better ball valve or gate valve

Because both gate valve and ball valve can be used after the regulating valve, the functions they undertake are basically similar. They are only different in structure, so users often have questions about whether to choose gate valve or ball valve. This is exactly what this article will discuss today. Before starting the problem, we should first make it clear that there is no better concept of which product is better for the gate valve or ball valve installed before and after the regulating valve. Only the more suitable one can be selected according to the actual situation of the user and the working conditions. Let’s first briefly understand the characteristics of gate valve and ball valve.

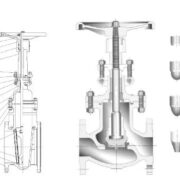

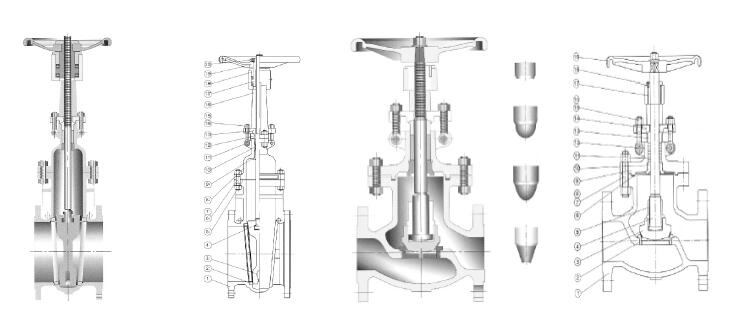

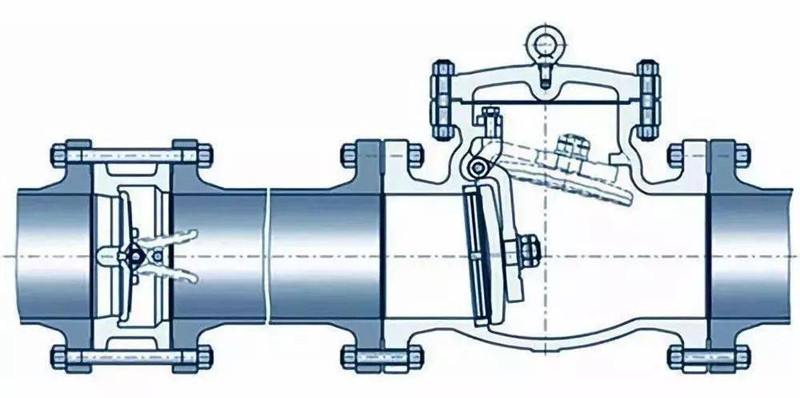

Functionally, the gate valve can be installed before and after the regulating valve, which is mainly used for water supply and hot water pipeline, commonly known as water valve. Generally, it is not used on the steam pipeline. The reason is that when the steam pressure is high, the ram is difficult to open under pressure. At the same time, it is not suitable to be used on the pipeline with sediment. Because the sediment is deposited in the ram seating groove, the RAM will not be closed tightly. The opening and closing part of the gate valve is the gate, and the movement direction of the gate is perpendicular to the fluid direction. The gate valve can only be fully opened and closed, not adjusted and throttled. The ball valve can also be installed before and after the regulating valve. It is mainly used to cut off, distribute and change the flow direction of the medium in the pipeline. It has the same action of rotating 90 degrees. The difference is that the cock body is a sphere with a circular through hole or channel passing through its axis.

From the point of view of advantages, the more prominent advantages of gate valve are small resistance, short size and low price. The relative advantage of ball valve is that its fluid control characteristics are better than gate valve. It only needs to rotate 90 degrees and a small rotating torque to close tightly. Ball valve is most suitable for switch and shut-off valve.

From the above, we can see that both gate valve and ball valve can be used before and after the regulating valve. These two valves are not suitable for flow control. However, the fluid control characteristics of ball valve are better than gate valve, and the tightness is also better than gate valve. However, in the actual installation case, although the gate valve and ball valve are installed before and after the regulating valve, the gate valve is more selected by the user. Why? The details are as follows:

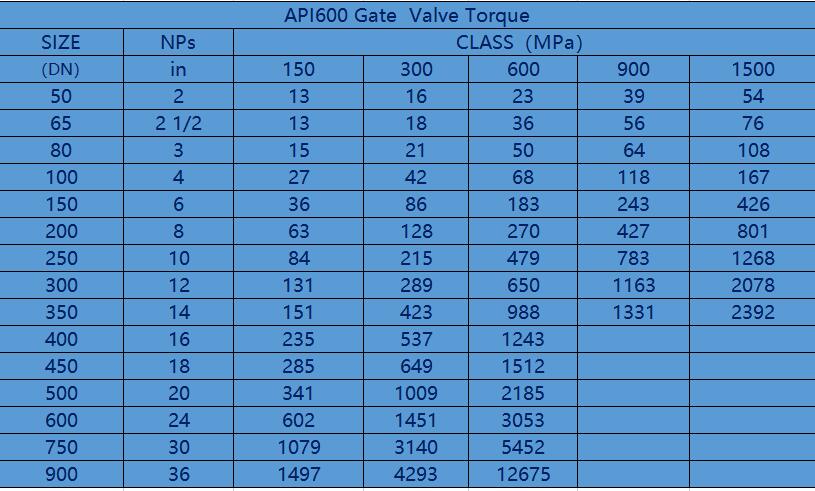

1. The ball valve is troublesome to open and close, and has high requirements for the sealing surface. The sealing of the ball valve has strict requirements on the production and processing process. If the right manufacturer is not selected, it is easy for the technology to fail to meet the requirements, resulting in internal leakage of the ball valve. Therefore, the cost is relatively high, especially the large-diameter ball valve. The gate valve has the advantages of low procurement cost, good sealing effect, labor-saving switching, and can provide the maximum overflow channel without resistance when the gate valve is fully open.

2. If the ball valve is in a static state for a long time, it will be stuck after being used for a period of time.

3. Ball valve has higher requirements for medium than gate valve. For example, ball valves can only be used for media containing more fiber and oxygen.

To sum up, the main differences between ball valve and gate valve lie in the differences in valve core, valve seat, stroke, actuator, medium flow direction, maintenance, etc. in general, it is better to install gate valve or ball valve before and after the control valve. Considering the economy, use gate valve, which is much cheaper. Or gate valves are selected for large-diameter and low-pressure oil, steam and water pipelines. Considering the tightness, the ball valve is used. The ball valve is suitable for working conditions, has high leakage level requirements, is suitable for rapid opening and closing, and its quality life is better than that of the gate valve.

Speak to one of STV’s knowledgeable advisers about your ball valve requirements today by calling 15157766245 or email sales@stvvalves.com.

FAQ

Can I use a ball valve instead of a gate valve?

Therefore, ball valves are better suited for applications like natural gas where a proper seal long-term is important. … However, for high pressure applications a gate valve is better suited. This is due to the fast opening/closing of the ball valve that may cause a water hammer.

When would you use a gate valve?

Gate valves are used when a straight-line flow of fluid and minimum flow restriction are needed. Gate valves use a sliding plate within the valve body to stop, limit, or permit full flow of fluids through the valve. The gate is usually wedge-shaped.

What is the best type of valve?

Ball valves are perhaps the most reliable type of valve and are commonly used for main water shutoffs and for branch line shutoffs. Like gate valves, a ball valve is designed as an all-or-nothing valve—they should be either fully open to allow full flow, or fully closed to stop all water flow.