Are you unsure of what type of Knife Gate is appropriate for your situation ?

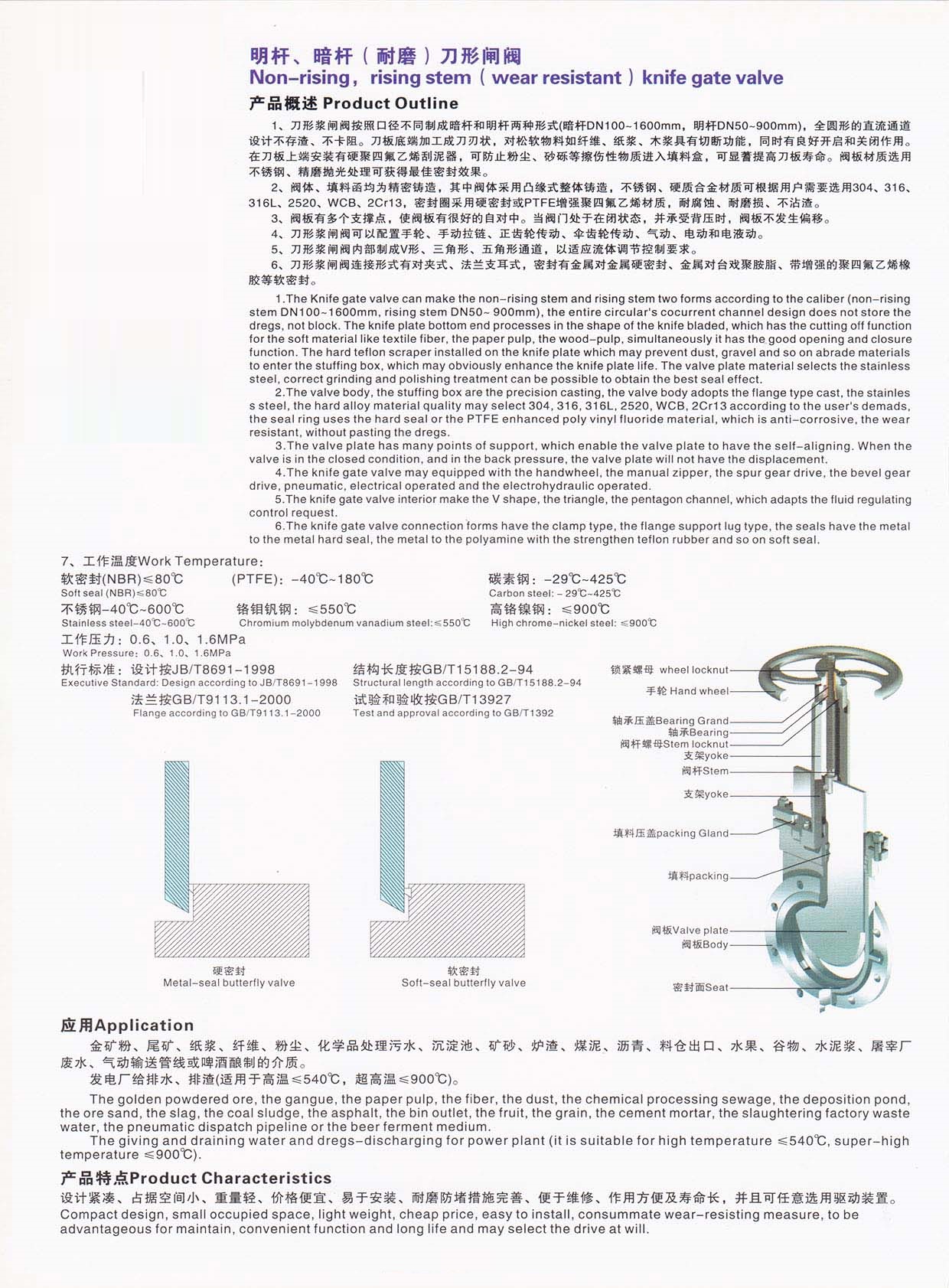

- Knife gate valves (commonly known as Slurry Valves) are used in a variety of difficult or severe applications. Knife Gate Valves are primarily used to permit or prevent the flow of slurry/liquids.

- However in certain non abrasive liquids (such as water) Knife Gate Valves are used for flow isolation as well as throttling/control duties in a limited way.

- Knife Gate Valves are generally not used in clean media where conventional valves are sufficient

Okay, so I need to figure out how to choose a knife gate valve. Let me start by recalling what a knife gate valve is. From what I remember, it’s a type of valve designed mainly for handling slurries, viscous fluids, and other media that might contain solids. The gate has a sharp edge that can cut through thick substances, hence the name “knife” gate valve.

First, I should consider the application. Where will this valve be used? If it’s for wastewater treatment, mining, pulp and paper industries, or any place dealing with sludges or abrasive materials, a knife gate valve might be the right choice. But I need to confirm that. Maybe other valves like ball valves or butterfly valves could be alternatives, but knife gates are better for certain conditions.

Next, the media type. The fluid’s characteristics are crucial. Is it a slurry, viscous, abrasive, or corrosive? Knife gate valves are good for thick and abrasive media, but if the fluid is highly corrosive, the material of the valve needs to resist that. So material compatibility is a big factor. Common materials might be stainless steel, cast iron, or maybe alloys with higher corrosion resistance. Also, temperature and pressure of the media matter. These valves are usually for low-pressure applications, right? So if the system has high pressure, maybe a different valve type is better.

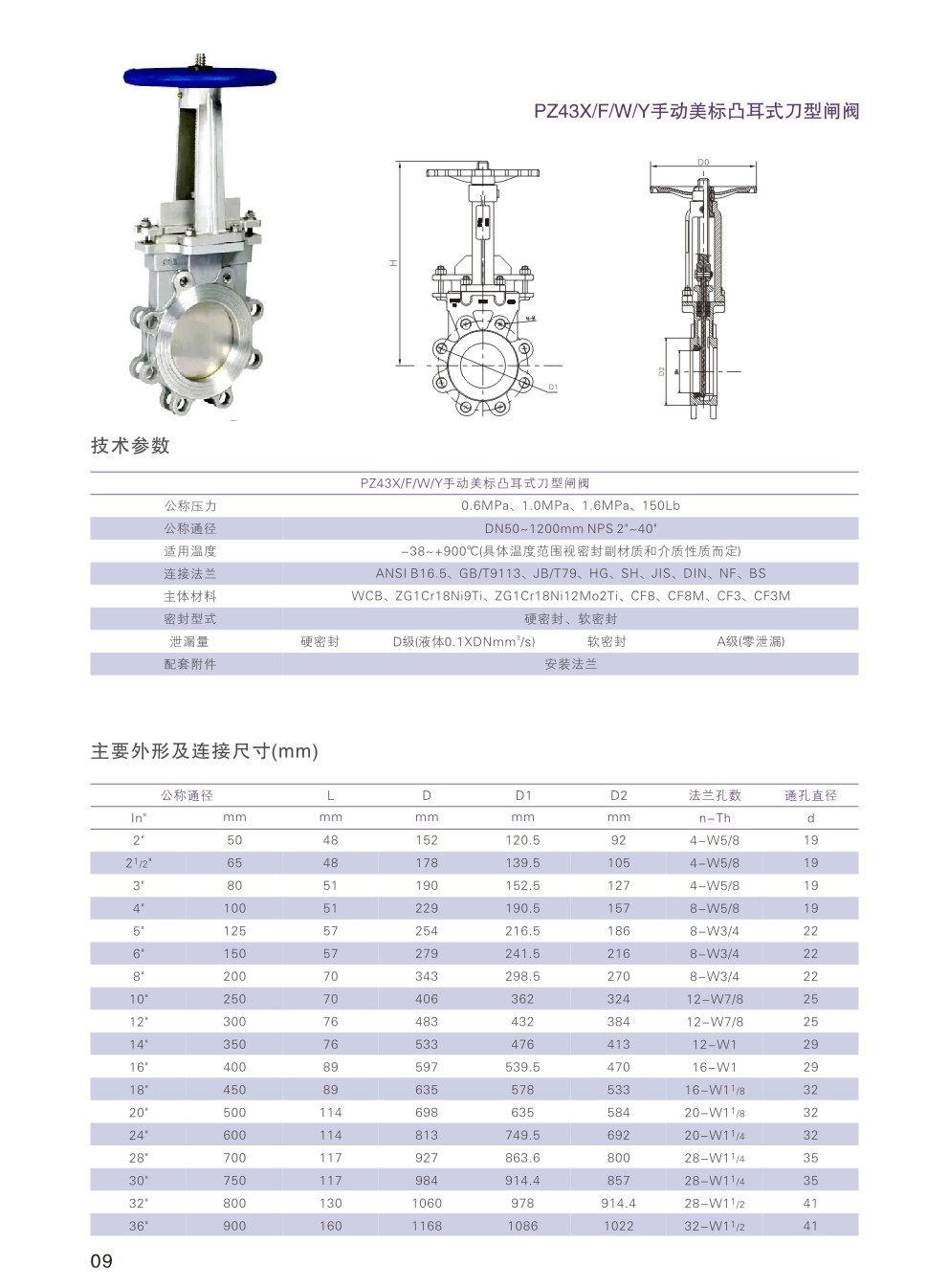

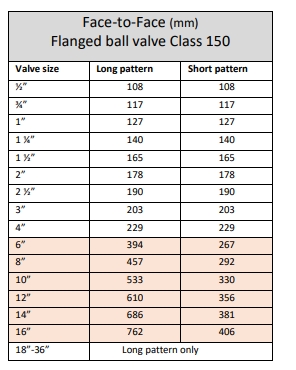

Size and pressure rating. The valve size should match the pipe diameter. But how do I determine the correct pressure rating? The valve must handle the maximum pressure in the system. But since knife gate valves are typically for low to medium pressure, I need to check the specs. Maybe PN10 or PN16 for metric, or Class 150 for ASME. If the system pressure is higher, this valve might not be suitable.

End connections. The valve needs to fit into the existing piping. Flanged ends are common, but there are also lug, wafer, or threaded types. Flanged might be better for larger sizes and easy maintenance. Threaded could be for smaller pipes. The user should check their piping standards to match the connection type.

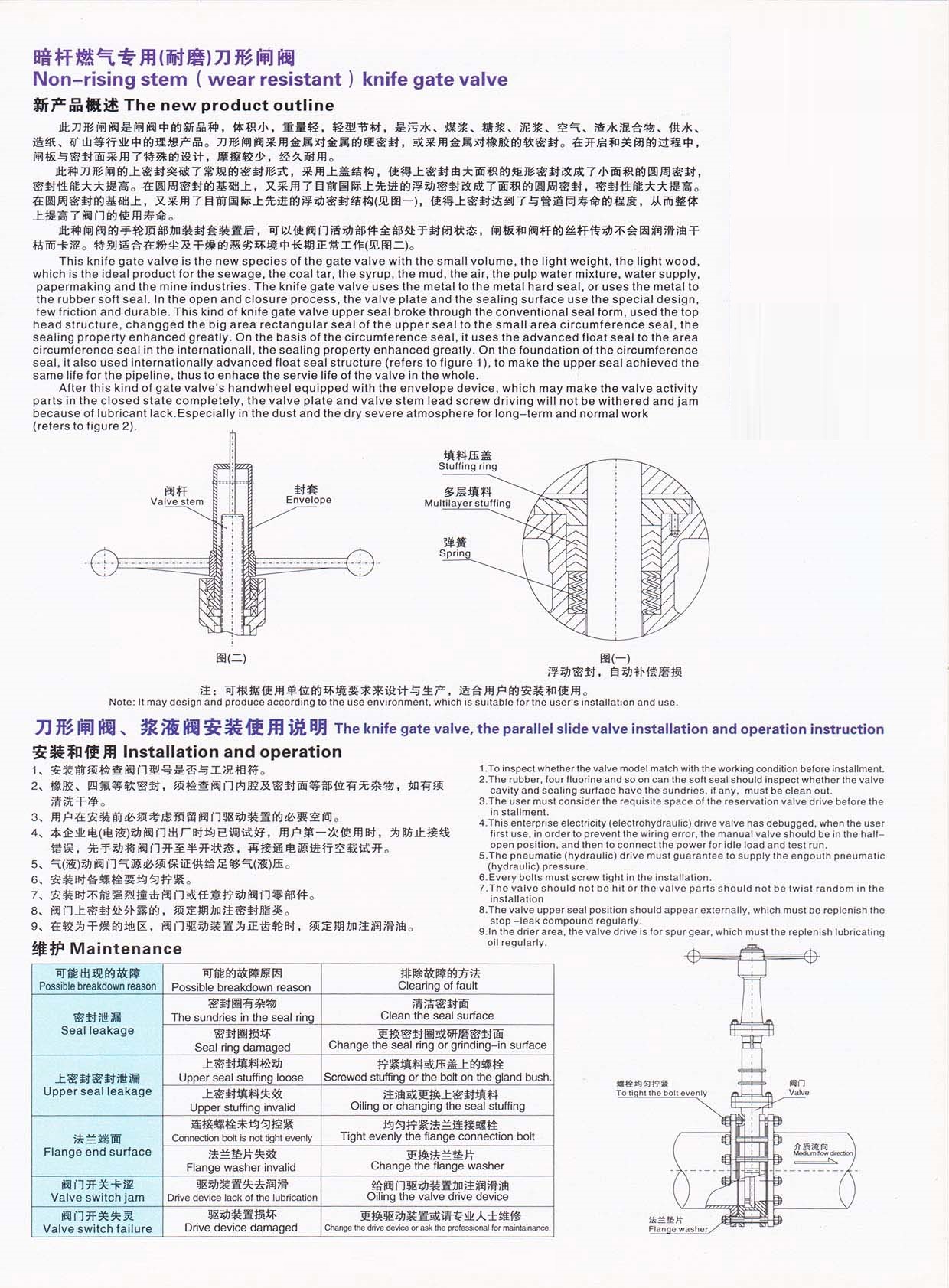

Sealing requirements. Knife gate valves can have different seals. Elastomers like EPDM, NBR, Viton, depending on the media. If the media is abrasive, maybe a metal seat is better. Also, consider if the valve needs to be bubble-tight or if some leakage is acceptable. For example, in slurry applications, a metal seat might handle abrasion better but might not seal as tightly as an elastomer. So the application’s leakage requirements matter.

Actuation type. Manual, pneumatic, electric, or hydraulic. Manual is cheaper and simpler but not feasible for remote or frequent operation. If the valve is in a hard-to-reach place or needs automation, then pneumatic or electric actuators are necessary. The choice depends on the available power sources and control systems.

Standards and certifications. Depending on the industry, there might be specific standards like API, ASME, ISO, or certifications for food processing, pharmaceuticals, etc. For example, in the food industry, FDA-approved materials might be required. Also, checking for fire-safe certifications if applicable.

Maintenance and durability. How easy is it to maintain the valve? Knife gate valves are supposed to have a simple design with fewer parts, which might make maintenance easier. But the materials should be durable enough to handle wear from abrasive media. Maybe the body is made of stainless steel for corrosion resistance, and the gate is hardened to resist abrasion.

Cost considerations. Initial cost vs. lifecycle cost. A cheaper valve might have higher maintenance costs or shorter lifespan. So balance between upfront investment and long-term reliability. Also, consider availability of spare parts and ease of replacement.

Manufacturer reputation and support. Choosing a reliable manufacturer with good customer service can be important for technical support and warranty issues. Maybe check reviews or industry recommendations.

Additional features. Some valves have a through-conduit design to prevent clogging, or a packing chamber that can be repacked under pressure. These features might be beneficial depending on the application.

Wait, I should structure these points more coherently. Let me outline the key factors step by step:

1. Application and media type: Ensure the valve is suitable for the intended use (slurries, viscous fluids) and compatible with the media’s properties (abrasive, corrosive, temperature, pressure).

2. Material selection: Choose body and seal materials that resist corrosion, abrasion, and temperature. Stainless steel, cast iron, alloys, and appropriate elastomers.

3. Size and pressure rating: Match the valve size to the pipe diameter and ensure the pressure rating exceeds the system’s maximum operating pressure.

4. End connections: Select the connection type (flanged, lug, wafer, threaded) based on existing piping and installation requirements.

5. Sealing mechanism: Decide between elastomer seals for tight shut-off or metal seats for abrasive media, considering leakage tolerance.

6. Actuation method: Manual for simplicity, automated (pneumatic/electric) for remote or frequent operation.

7. Standards and certifications: Compliance with industry standards and necessary certifications (API, ASME, FDA, etc.).

8. Maintenance and durability: Evaluate ease of maintenance, expected lifespan, and availability of spare parts.

9. Cost and manufacturer: Balance initial cost with reliability, and choose reputable manufacturers for support.

10. Additional features: Through-conduit design, repairable packing, fire-safe design, etc., based on specific needs.

I might have missed something. Let me check. Oh, maybe the flow direction? Some knife gate valves are uni-directional, so the installation direction matters. They should be installed with the flow in the correct direction to ensure proper sealing and function. Also, consider if the valve is for isolation only, not for throttling. Knife gates are typically on/off, not for flow control.

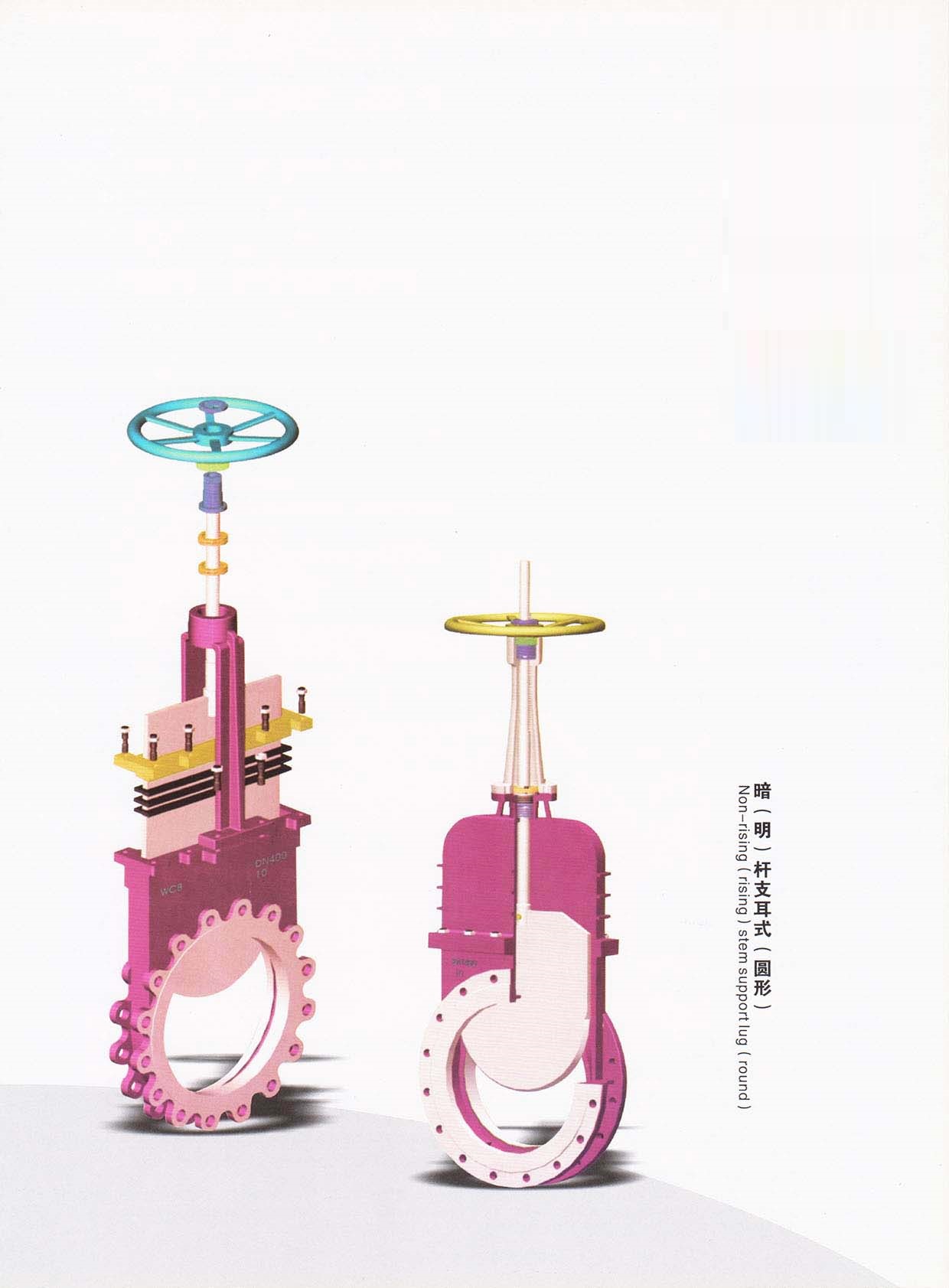

Another point: the type of knife gate valve. There are different designs like non-rising stem vs rising stem. Non-rising is better where vertical space is limited. Also, some have a spring-loaded gate to assist in sealing. These design variations could affect the selection based on installation constraints.

Also, consider the valve’s ability to handle solids. The knife edge should be able to cut through any solids in the media without getting stuck. So the clearance and design of the gate and seat are important.

In summary, the selection process involves understanding the application requirements, media characteristics, operational parameters (pressure, temperature), material compatibility, installation considerations, actuation needs, and compliance with standards. It’s a balance between all these factors to choose the most suitable knife gate valve for the specific use case.