Analysis of Forged Steel Ball Valves and Cast Steel Ball Valves

What is the difference between a forged steel ball valve and a cast steel ball valve? Mainly for the forging process and processing form of steel:

Forged steel ball valves are steel used to cast castings. A type of casting alloy. Cast steel is divided into cast carbon steel, cast low alloy steel and cast special steel. Cast steel refers to a steel casting produced by a casting method. Cast steel is mainly used to make parts that are complex in shape, difficult to forge or cut, and require high strength and plasticity.

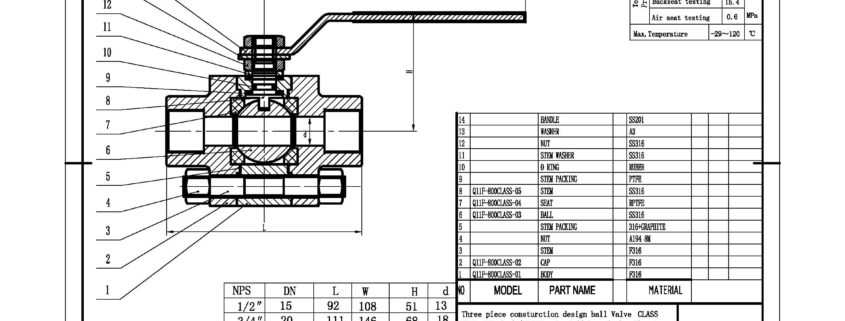

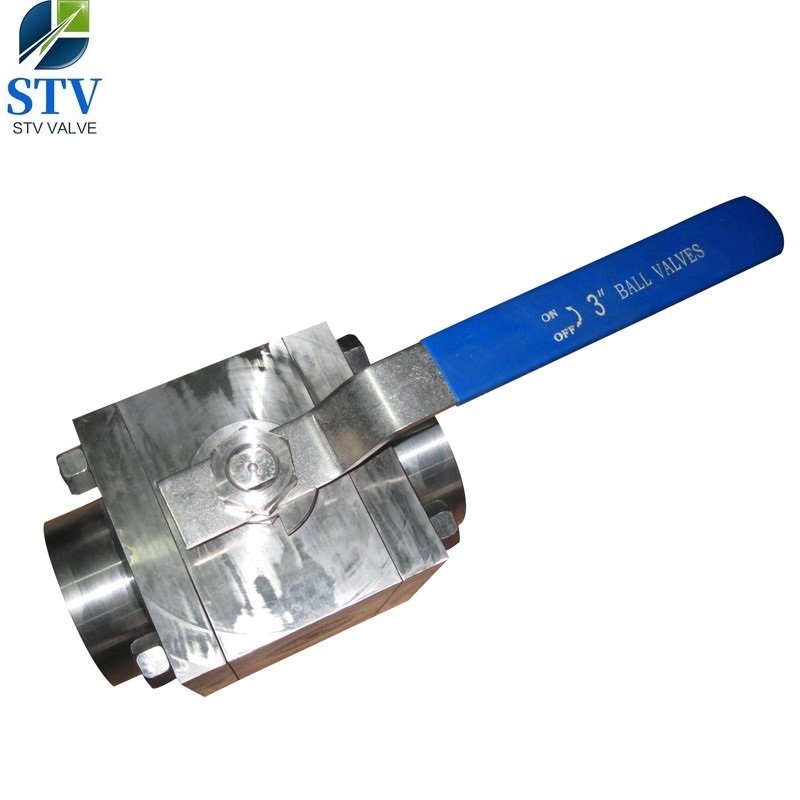

Forged steel ball valve /

Forged steel ball valves are various forgings and forgings produced by forging methods. Forged steel ball valves are higher in mass than cast steel ball valves and can withstand large impact forces. Plasticity, toughness and other mechanical properties are also higher than steel castings. Therefore, for some important machine parts, forged steel parts should be used.

Casting is liquid molding, and forging is a plastic deformation process. The forged workpiece can improve the internal structure of the structure, the mechanical properties are good, the grains are uniform, and the important laborious workpiece must be forged. The casting will cause structural segregation, structural defects, and of course, casting has its advantages. The forming of complex workpieces is not easy to mold and has been cast.